Brief Introduction

E-ASIA Cylindrical Roller Bearings represent a precision-engineered solution for applications demanding high radial load capacity and operational reliability. As a specialized rolling bearing design, these components deliver exceptional load distribution through line contact between rollers and raceways, making them the preferred choice for electric motors, gearboxes, and heavy industrial machinery. Built with 60 years of bearing manufacturing expertise, each unit undergoes 100% quality inspection to ensure dimensional accuracy and performance consistency. These bearings accommodate heavy radial forces while maintaining precise shaft positioning, enabling smooth rotation in environments where downtime carries significant operational costs. Their separable design facilitates installation and maintenance, reducing assembly time and extending equipment service life across diverse industrial sectors.

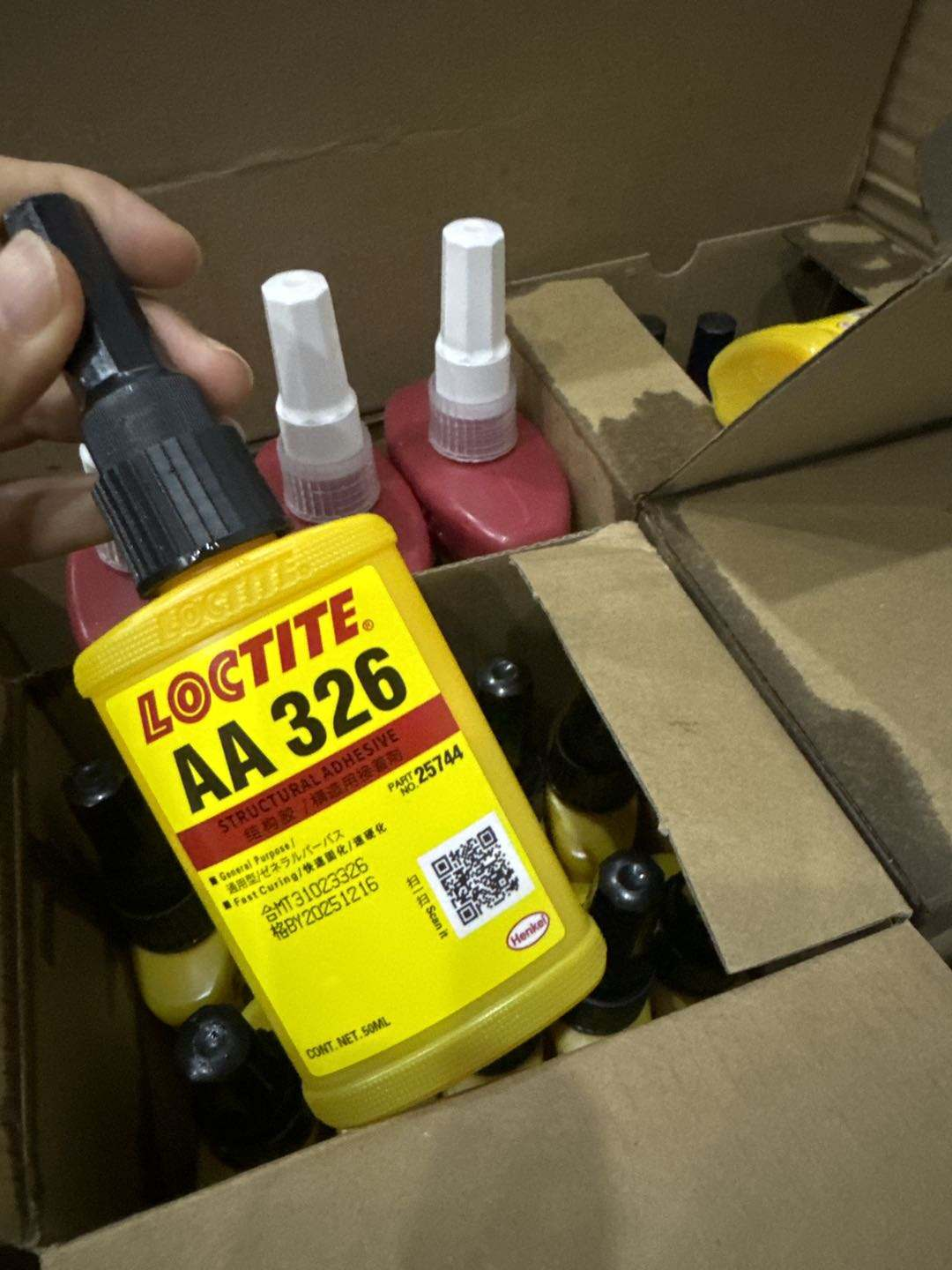

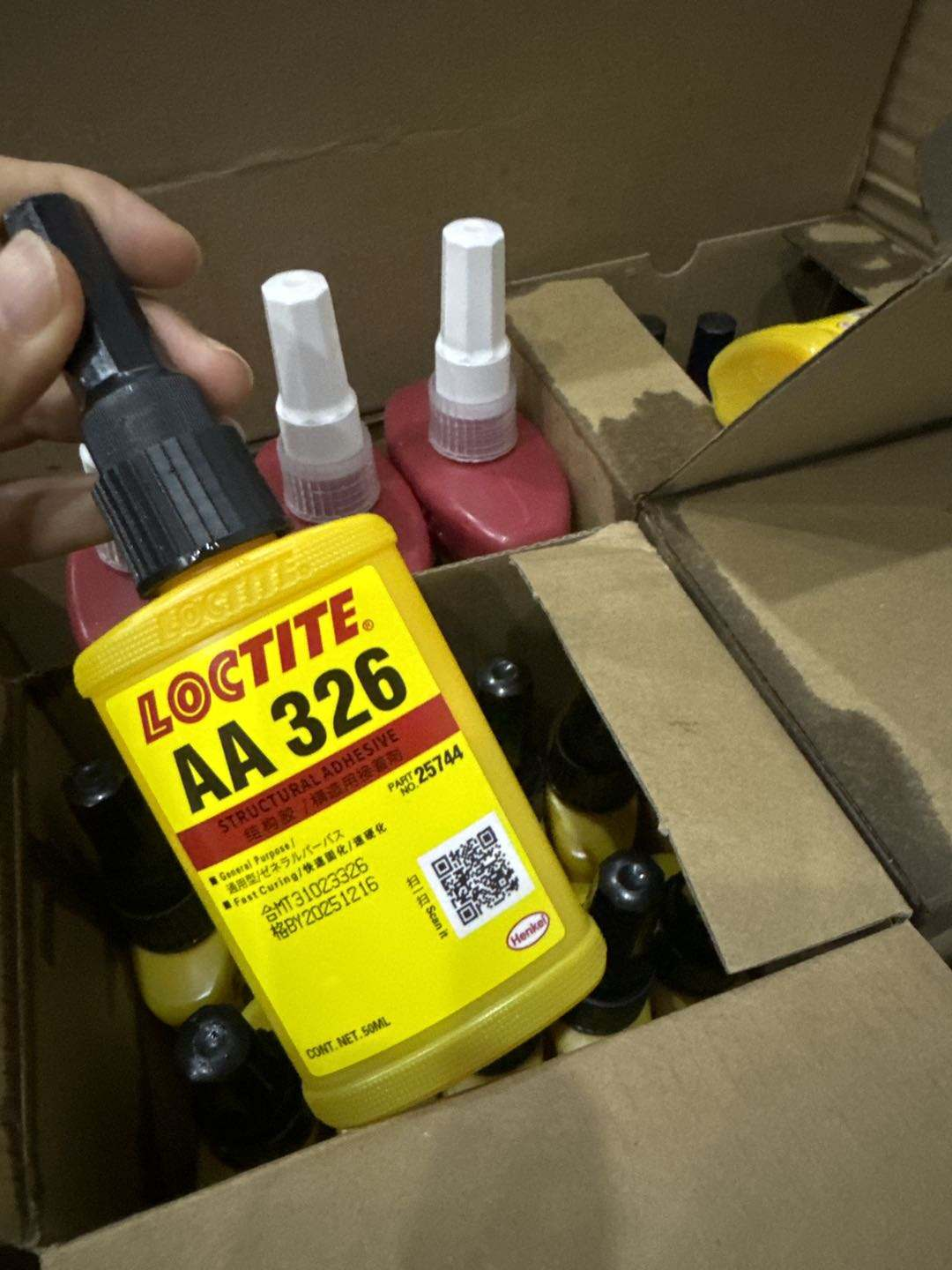

| Applications | Structural bonding |

| Chemical basis / base | Methacrylate |

| Color | Amber, Yellow |

| Cure type | Activator cure, Anaerobic cure |

| FEA (finite element analysis) | Finite strain, Viscoelastic |

| Fixture time | 3.0 min. |

| Key characteristics | Mix: no mix required |

| Shear strength | 15.0 N/mm² |

| Viscosity, Brookfield - RVT, @ 25.0 °C Spindle 6, speed 20 rpm | 14000.0 - 22000.0 mPa·s (cP) |

| Viscosity, EN 12092 - MV, @ 25.0 °C Shear Rate 36 s⁻¹ | 10000.0 - 20000.0 mPa·s (cP) |

Core Features

Superior Radial Load Handling

The defining characteristic of cylindrical roller bearings lies in their exceptional radial load capacity, achieved through line contact between cylindrical rollers and machined raceways. This contact geometry distributes forces across greater surface area compared to point-contact ball bearings, enabling these bearings to support loads 50-70% higher within equivalent dimensional envelopes. The parallel alignment of rollers ensures uniform load sharing across all rolling elements, preventing premature wear and extending operational life in heavy-duty applications.

Minimal Axial Constraint Design

Unlike ball bearings that resist thrust forces, most cylindrical roller configurations allow free axial displacement between shaft and housing, accommodating thermal expansion without inducing internal stress. This design feature proves critical in long shaft applications where temperature variations would otherwise create dimensional conflicts. Available configurations include fixed-end designs (with integral flanges on both rings) for applications requiring axial positioning, and floating-end arrangements that permit shaft movement while maintaining radial support.

Separable Ring Construction

The separable design of inner ring, outer ring, and roller cage assembly enables independent mounting of bearing components, simplifying installation on assembled shafts or within closed housings. Maintenance procedures benefit from this feature, allowing inspection or replacement of individual components without complete equipment disassembly. This characteristic reduces installation time by 40-60% compared to non-separable bearing types in many applications.

Optimized for High-Speed Performance

Precision-ground roller profiles and balanced cage designs enable operation at elevated speeds while maintaining stability and minimal vibration. Advanced cage geometries reduce friction between rollers and guide surfaces, lowering operating temperatures and power consumption. Modified roller crowning prevents edge stress concentrations that would generate heat and noise at high rotational velocities, making these bearings suitable for motor speeds exceeding 15,000 rpm in appropriate sizes.

Typical Uses

Electric Motor Applications

Cylindrical roller bearings serve as primary shaft support in industrial electric motors ranging from 5 kW to 5,000 kW power ratings. The high radial capacity accommodates magnetic pull forces and belt tension in motor drives, while the free axial displacement accommodates thermal shaft expansion during operation. Motors for fans, pumps, compressors, and conveyors rely on these bearings to maintain air gap consistency between rotor and stator, ensuring electrical efficiency and preventing catastrophic contact. Service life in motor applications typically exceeds 50,000 operating hours when properly specified and maintained.

Gearbox and Transmission Systems

Industrial gearboxes, particularly parallel-shaft and planetary configurations, utilize cylindrical roller bearings to support heavy gear loads while maintaining precise shaft alignment. The rigid radial support minimizes shaft deflection that would cause gear tooth misalignment and accelerated wear. Automotive transmissions, wind turbine gearboxes, and marine reduction units depend on these bearings to transmit torque efficiently while withstanding shock loads from rapid acceleration or load changes. The separable design facilitates gearbox assembly, allowing bearing outer rings to be installed in housing bores before shaft insertion.

Machine Tool Spindles

Precision cylindrical roller bearings in machine tool spindles provide the rigidity necessary for accurate metal cutting operations. Main spindle applications in lathes, milling machines, and grinding equipment require bearings that resist cutting forces without deflection while rotating at speeds appropriate for tooling requirements. Matched bearing sets installed in tandem or back-to-back configurations eliminate axial play, achieving positional accuracy within micrometers. Precision class P5 or P4 bearings ensure spindle runout remains below 2 micrometers, critical for surface finish quality.

Heavy Industrial Machinery

Mining equipment, steel mill roll necks, and construction machinery subject bearings to extreme radial loads combined with shock impacts. Cylindrical roller bearings in these applications feature robust cage designs and generous internal clearances to accommodate deflection and thermal expansion. Rolling mill applications may see roller bearings supporting loads exceeding 1,000 kN while rotating continuously for weeks between maintenance intervals. The line contact load distribution prevents the surface fatigue that would rapidly destroy ball bearings under equivalent conditions.

Rail and Transportation Systems

Railway axle boxes, traction motors, and wheel hub assemblies incorporate cylindrical roller bearings sized to support vehicle weight and dynamic loads from track irregularities. High-speed rail applications demand bearings that operate reliably at sustained speeds exceeding 300 km/h while maintaining dimensional stability across wide temperature ranges. Freight applications prioritize load capacity and contamination resistance, with sealed bearing variants protecting against environmental contaminants encountered in rail operations.

Material and Manufacturing Process

Raw Material Selection

Inner and outer rings begin as forged steel billets sourced from qualified mills with certified chemical composition. The bearing steel (typically GCr15, AISI 52100, or equivalent) contains 0.95-1.05% carbon and 1.35-1.60% chromium, providing the hardness and wear resistance required for bearing applications. Vacuum degassing during steel production minimizes non-metallic inclusions that could initiate fatigue cracks, ensuring material cleanliness meets or exceeds international standards.

Precision Turning Operations

CNC turning centers machine ring blanks to near-final dimensions, establishing raceway diameter, bore, outer diameter, and width within tight tolerances. Machining operations account for subsequent heat treatment distortion, with pre-heat treatment dimensions calculated to achieve final specifications after thermal processing. Inner ring bores receive precision boring to h6 or h7 tolerance, ensuring proper shaft fit without excessive interference that would reduce internal clearance.

Heat Treatment Cycle

Rings undergo through-hardening heat treatment, heated to 830-860°C in controlled atmosphere furnaces to prevent surface decarburization. Quenching in oil or polymer solutions achieves martensitic transformation, then tempering at 150-180°C relieves internal stress while maintaining surface hardness of 58-65 HRC. Large bearings may receive carburizing treatment for enhanced surface properties while retaining core toughness. Post-heat treatment stress relieving prevents dimensional changes during service that could affect clearance and preload.

Raceway Grinding Process

Precision grinding operations achieve final raceway geometry and surface finish, with multi-stage processes progressing from rough grinding through fine finishing. Raceway profiles maintain straightness within 5 micrometers across the full width, ensuring even load distribution along roller length. Surface roughness values typically reach Ra 0.2 micrometers or better, minimizing friction and extending rolling contact fatigue life. Automated measuring systems verify dimensions during grinding, with statistical process control preventing dimensional drift.

Roller Manufacturing

Cylindrical rollers start as cold-headed wire segments, then undergo centerless grinding to achieve diameter precision within 2-3 micrometers. Roller ends receive radius grinding or chamfering to prevent stress concentrations during operation. Length grinding ensures uniform roller dimensions within matched sets, with variation limited to 5 micrometers to maintain even load distribution. Modified roller profiles incorporate slight crowning (5-15 micrometers) to prevent edge loading under deflection or misalignment conditions.

Cage Fabrication

Pressed steel cages utilize cold-forming processes to create pocket geometries that guide rollers while minimizing friction. Brass cages, machined from solid bar stock or centrifugally cast, offer superior strength and heat dissipation for high-speed applications. Polyamide cages provide lightweight construction with reduced noise generation, suited for electric motor applications where acoustic performance matters. Cage pocket clearances balance roller guidance against friction, with tighter tolerances for high-speed operation and looser clearances for shock-loaded applications.

Final Assembly Quality Control

Assembled bearings undergo comprehensive inspection including dimensional verification, internal clearance measurement, and vibration testing. Automated vibration analyzers detect microscopic defects through frequency spectrum analysis, rejecting units that exceed specified vibration limits. Visual inspection confirms proper cage operation and absence of surface defects. Batch traceability links finished bearings to raw material lots and processing parameters, enabling quality investigation if field issues arise.

Installation Best Practices

Shaft and Housing Fit Selection

Proper fit selection between bearing rings and mounting surfaces directly impacts bearing performance and life. Inner rings rotating relative to load typically require interference fits (j5, k5, m5, or n6), with tighter fits for heavy loads or solid shafts and looser fits for hollow shafts prone to stress concentration. Stationary outer rings accept transition or clearance fits (J6, J7, K6), with housing material thermal expansion characteristics influencing fit selection. Fit tolerances must account for bearing internal clearance reduction caused by ring expansion and contraction during installation.

Thermal Mounting Methods

Heating inner rings to 80-100°C above ambient temperature (maximum 120°C) expands the bore for interference fit installation without mechanical force. Induction heaters or oil baths provide controlled, uniform heating while avoiding localized overheating that could affect material properties. Rapid installation while the ring remains expanded prevents cooling-induced seizure on the shaft. External ring heating enables outer ring installation in housings, though cold shrinking the housing provides an alternative for large bearings.

Mechanical Mounting Procedures

Hydraulic installation tools apply mounting force through the fitted ring face, distributing pressure evenly around the circumference. Installation sleeves prevent damage to ring faces and raceways during press fitting. Force monitoring during installation detects abnormal resistance indicating fit issues or contamination. Never apply mounting force through rollers or the non-fitted ring, as this creates damaging indentations (false brinelling) on raceways that accelerate wear.

Lubrication Application

Initial lubrication type and quantity affect bearing performance and service life. Grease lubrication suits applications below 70% of the bearing's grease speed rating, with fill quantities of 30-50% of available space for moderate speeds and lower fill for high-speed operation. Oil lubrication via circulation, mist, or jet systems enables operation at higher speeds while providing cooling and contamination removal. Minimum oil viscosity at operating temperature should provide adequate film thickness, typically 12-20 mm²/s depending on speed and load conditions.

Alignment Verification

Shaft and housing alignment within 0.002-0.003 radians prevents edge loading that would cause premature raceway wear. Dial indicator measurements confirm concentricity and perpendicularity of mounting surfaces before installation. Temperature monitoring during initial operation identifies misalignment through abnormal heat generation, typically indicating need for realignment before permanent damage develops. Vibration analysis during commissioning establishes baseline signatures for condition monitoring programs.

Comparison with Alternative Bearing Solutions

Cylindrical Roller vs Deep Groove Ball Bearings

While deep groove ball bearings handle combined radial and thrust loads in compact designs, cylindrical roller bearings provide 50-70% higher radial capacity within the same envelope dimensions. Ball bearings suit applications with moderate loads and bidirectional thrust requirements, whereas cylindrical roller bearings excel in heavy radial load applications with minimal thrust forces. Speed capability generally favors ball bearings for small sizes, though large cylindrical roller bearings achieve comparable speeds with appropriate cage design. Installation simplicity advantages ball bearings in applications where separable design provides no benefit.

Cylindrical Roller vs Tapered Roller Bearings

Tapered roller bearings combine radial and thrust load capacity, making them suitable for applications with significant axial forces like vehicle wheel hubs. Cylindrical roller bearings provide higher pure radial capacity and accommodate shaft thermal expansion without thrust load generation. Tapered roller bearings require preload adjustment and paired mounting in most applications, adding complexity compared to single cylindrical roller bearing installations. Cost considerations typically favor cylindrical roller bearings where thrust loads remain minimal.

Cylindrical Roller vs Spherical Roller Bearings

Spherical roller bearings accommodate shaft misalignment up to 1-2 degrees through their self-aligning capability, beneficial in applications with shaft deflection or mounting surface irregularities. Cylindrical roller bearings demand precise alignment but offer higher speed capability and lower friction in properly aligned systems. Radial capacity per unit width favors spherical roller bearings, though cylindrical roller bearings provide comparable capacity in less radial space when alignment conditions permit their use.

Cylindrical Roller vs Needle Roller Bearings

Needle roller bearings offer extremely high radial capacity within minimal radial envelope, suited for space-constrained applications. Cylindrical roller bearings provide greater length-to-diameter roller ratios, reducing edge stress and enabling higher speed operation. Needle bearings typically require external shaft and housing surfaces as raceways or thin-section rings, while cylindrical roller bearings incorporate integral raceways for superior durability. Applications with severe space constraints favor needle bearings, whereas general industrial machinery benefits from cylindrical roller bearing robustness.

Precautions

Activation with Recommended Primer

LOCTITE AA 326 requires activation with LOCTITE SF 7649 primer for optimal performance. Ensure the primer is applied correctly and allowed to dry according to instructions before applying the adhesive. Using an incorrect primer or skipping this step can significantly reduce bond strength.

Safe Handling & Storage

Wear protective gloves, goggles, and a respirator when working with this adhesive to avoid skin contact, eye irritation, and inhalation of fumes. Store in a cool, dry place away from heat, sparks, and open flames. Keep containers tightly sealed when not in use to prevent contamination or premature curing.

Surface Preparation

For best results, clean and degrease all bonding surfaces thoroughly before application. Remove any dirt, rust, or oil, as contaminants can weaken the bond. Lightly abrading smooth surfaces can enhance adhesion, ensuring a stronger, longer-lasting bond.

FAQ

Do I need to mix LOCTITE AA 326 before use?

A1: No, this structural glue requires no mix required—it is ready to use straight from the container, simplifying application and reducing workflow time.

What is the recommended primer for this adhesive?

LOCTITE AA 326 must be activated with LOCTITE SF 7649 primer to achieve maximum bond strength. Using any other primer may not yield optimal results.

Can it bond materials other than metal?

While it is primarily designed for metal-to-metal bonding and adhesion to ferrites, it can bond some plastics and composites. For non-metallic substrates, test compatibility on a small sample first.

Is it suitable for high-temperature environments?

Yes, it offers reliable temperature resistance for moderate heat conditions, making it suitable for applications where components may be exposed to elevated temperatures during operation.

Why Choose E-ASIA Cylindrical Roller Bearings

Proven Manufacturing Heritage

E-ASIA brings six decades of bearing production experience to every cylindrical roller bearing manufactured in our facilities. This accumulated knowledge base informs material selection, heat treatment protocols, and quality control procedures that deliver consistent performance across production lots. Our quality management systems evolved alongside international bearing standards, achieving ISO 9001 certification and maintaining continuous improvement processes that reduce variation and enhance reliability. Manufacturing expertise developed across generations ensures each bearing meets or exceeds published specifications.

Comprehensive Application Engineering

Our technical team collaborates with customers to optimize bearing selection for specific operating conditions, calculating expected service life and recommending mounting practices that maximize performance. We provide detailed installation instructions, lubrication recommendations, and troubleshooting guidance to support successful implementation. Failure analysis services investigate returned bearings to identify root causes and prevent recurrence in future designs. Training programs educate maintenance personnel on proper handling techniques, installation procedures, and condition monitoring approaches that extend bearing life.

Flexible Supply Capabilities

Direct factory sourcing combined with strategically positioned inventory enables rapid response to both planned and emergency bearing requirements. Stock bearings ship within 24 hours for urgent needs, while custom specifications receive priority scheduling to minimize lead times. Volume production capacity supports large OEM programs with consistent quality and delivery reliability, while small-batch capabilities serve distributor and aftermarket channels. Technical support assists with bearing selection, mounting procedures, and performance optimization throughout the product lifecycle.

Competitive Value Proposition

Factory-direct pricing eliminates distributor markups while maintaining quality standards equal to premium bearing brands. Our cost structure reflects efficient manufacturing operations and strategic raw material sourcing, delivering price advantages of 15-30% compared to equivalent imported bearings. This value proposition extends beyond initial purchase price to include total cost of ownership, with reliable performance reducing maintenance frequency and unplanned downtime costs. We provide technical support and application engineering at no additional charge, enhancing value through successful implementation.

Global Distribution Network

Warehouse facilities positioned across major industrial regions ensure local stock availability and rapid delivery to customers worldwide. Regional technical representatives provide application assistance in local languages and time zones, facilitating communication and problem resolution. Logistics partnerships support express shipping, standard freight, and economical ocean transport options scaled to delivery urgency. Customs documentation expertise streamlines international shipments, minimizing border delays that could impact production schedules.

Contact E-ASIA Bearing today for technical specifications, application consultation, or volume pricing on cylindrical roller bearings. Our bearing specialists stand ready to support your equipment reliability objectives with products proven across industries worldwide. Request your quote now to experience the E-ASIA difference in bearing quality and customer service.

English

English