Selecting the correct replacement bearing often seems simple. You measure the shaft diameter, confirm it is exactly one inch, and order a standard unit. However, when the part arrives, the bolt holes might not align, or the center height sits too low. Even worse, the unit fits perfectly but fails within weeks because the internal insert could not handle the axial thrust load. This is the high cost of specification mismatch. While "1 inch" specifies the bore, it tells you nothing about the housing style, material durability, or dynamic load ratings necessary to keep your machinery running.

This guide moves beyond basic shaft sizing. We explore the critical load dynamics, environmental factors, and housing geometries that determine component lifespan. Whether you are a maintenance engineer reducing downtime or a procurement specialist seeking value, this information ensures you choose high-reliability components. You will learn to navigate the complex trade-offs between material cost and operational longevity.

Key Takeaways

Shaft Size is Just the Start: A 1-inch shaft fits multiple housing series (200 vs. 300); verifying bolt hole spacing and center height is critical.

Load Direction Matters: Ball bearing inserts suit radial loads/high speed; spherical rollers are required for heavy axial loads or misalignment.

Environment Dictates Material: Cast iron fails in washdowns; specify stainless steel or thermoplastic for food/pharma, and zinc alloy for light-duty HVAC.

Decoding the Code: Understanding prefixes like UCP vs. HCP prevents ordering incompatible locking mechanisms (set screw vs. eccentric collar).

Beyond Shaft Diameter: Critical Sizing Dimensions for 1 Inch Bearings

Many buyers fall into the trap of thinking all 1-inch bearings are interchangeable. In reality, the bore diameter is the only constant. The housing surrounding that bore varies significantly based on the intended duty cycle. Ignoring these external dimensions is the leading cause of installation frustration and immediate equipment binding.

The "Series" Trap

Manufacturers produce bearings in different series, typically labeled as "Standard Duty" (200 Series) or "Medium/Heavy Duty" (300 or X Series). A standard 200-series housing is compact and sufficient for most conveyors and fans. However, heavy-duty applications often use a physically larger housing to support a 1-inch shaft.

If you try to mount a standard duty 1 Inch Pillow Block Bearing into a space designed for a medium-duty unit, the bolt holes will not line up. Conversely, installing a heavy-duty unit in a tight space might cause interference with other machine parts. Always check the series number stamped on the housing, not just the shaft size.

Bolt Hole Center-to-Center

The distance between the mounting bolts is the "footprint" of your bearing. Two housings can have the same bore and look identical but feature bolt spacing that differs by a fraction of an inch. This dimension is rarely adjustable on the machine frame.

You must measure from the center of one slot to the center of the other. Be aware that some housings use 2-bolt configurations while others use 4-bolt flanges. Assuming a "standard" footprint often leads to wasted budget on non-returnable parts. Careful measurement ensures your new Housing pillow block bearing drops directly onto the existing mounting studs without modification.

Base-to-Center Height

This is arguably the most critical and overlooked dimension. It measures the vertical distance from the mounting surface (the base) to the exact center of the shaft. If your replacement unit is even 1/16th of an inch lower or higher than the original, the shaft will not sit level.

Mismatching this height forces the shaft to bend to fit the bearing. This creates a "pre-load" condition where the bearing is under massive stress before the machine even turns on. The result is excess heat, vibration, and rapid failure. Always verify the base-to-center height matches your original specification exactly.

Matching the Insert Type to Load and Speed Dynamics

The housing holds the bearing, but the insert does the work. Choosing the right insert technology depends entirely on how your equipment moves and the forces it encounters. We categorize these into ball, roller, and plain bearing types.

| Insert Type | Primary Load | Speed Capability | Misalignment Tolerance |

| Deep Groove Ball | Radial (Moderate) | High | Low (+/- 2 deg) |

| Spherical Roller | Radial + Axial (Heavy) | Low to Moderate | High |

| Tapered Roller | Combined Heavy Loads | Moderate | Low |

Ball Bearing Inserts (Deep Groove)

Deep groove ball bearings are the industry standard for a reason. They offer low friction, which allows for high rotational speeds. They are excellent for fans, light conveyors, and electric motors where the primary force is radial (perpendicular to the shaft).

However, ball bearings have limited surface contact. If your application involves heavy thrust loads (force pushing along the shaft) or significant shock vibration, balls can deform or spall. In these high-stress scenarios, a ball insert will wear out prematurely.

Roller Bearing Inserts (Spherical & Tapered)

When loads get heavy, you need more contact area. Roller bearings use cylinders rather than spheres, distributing the weight across a line rather than a point. This makes them ideal for a Heavy-Duty Plummer pillow block bearing found in mining crushers or heavy aggregate conveyors.

Spherical roller inserts offer a distinct advantage: self-alignment. They can handle shaft deflection—bending under load—without seizing. If your shaft is long or the mounting surface isn't perfectly flat, a spherical roller unit forgives these imperfections better than any other type.

Plain vs. Linear Options

Not all pillow blocks rotate. Some are designed for linear motion, sliding back and forth along a rail. In these applications, the "binding ratio" becomes critical. This refers to the distance of the load from the bearing relative to the bearing length. If the ratio is off, the bearing will lock up.

For automated machinery requiring extreme accuracy, you might look for a High-Precision pillow block bearing. These units have tighter manufacturing tolerances to reduce play and vibration, which is essential for CNC equipment and robotics where positioning accuracy is paramount.

Housing Materials and Environmental Resistance

The environment surrounding your equipment is just as important as the load it carries. A bearing that mechanically handles the weight will still fail if the housing corrodes or the grease washes away.

Cast Iron (The Industry Standard)

Cast iron is the default material for general machinery. It is strong, rigid, and offers excellent vibration damping properties. It absorbs the noise and shake of rotating equipment, protecting the frame. It is also the most cost-effective option.

The trade-off is corrosion. Cast iron is porous and rusts quickly when exposed to water or high humidity. It is generally unsuitable for food processing washdowns or outdoor marine applications unless painted or coated heavily.

Stainless Steel & Thermoplastic

For industries regulated by the FDA or those operating in wet environments, you must move away from cast iron. Stainless steel housings resist rust and chemicals, making them capable of withstanding caustic cleaning agents.

Thermoplastic housings are another option. They are lightweight, rust-proof, and often cheaper than stainless steel. However, they cannot handle the same heavy loads or impact forces. In applications with extreme heat, you might also need a High Temperature Resistance pillow block bearing. These units feature special internal clearances, Viton seals, and high-temp grease to prevent seizing when temperatures exceed standard operating limits.

Pressed Steel vs. Zinc Alloy

For lighter duties, heavy cast housings are overkill. Pressed steel housings are formed from sheet metal. They are lightweight and inexpensive, making them perfect for simple applications like HVAC fan supports.

Zinc alloy (Zamak) offers a middle ground. It is cleaner and more corrosion-resistant than cast iron but lighter duty. You often see zinc housings in light manufacturing and clean environments where painting cast iron is not an option, but the cost of stainless steel is not justified.

Decoding Part Numbers: UCP, UCF, and Locking Mechanisms

Bearing part numbers look like random codes, but they follow a strict logic. Understanding this syntax helps you verify you are ordering the correct item without needing to see it physically.

Understanding the Syntax (Example: UCP205-16)

Let's break down a common code like UCP205-16. This logic applies across most major brands.

UC: This indicates the insert type. "UC" typically denotes a set screw locking mechanism with a wide inner ring.

P: This describes the housing shape. "P" stands for Pillow Block (Pedestal). "F" would mean a 4-bolt Flange, and "FL" would be a 2-bolt Flange.

205: This is the series size. A "205" is a specific physical size. A "206" would be physically larger and handle more load.

-16: This represents the bore size in 16ths of an inch. A "-16" means 16/16ths, or exactly 1 inch.

Locking Mechanism Selection

The way the bearing grips the shaft is crucial. The standard "UC" style uses set screws. These bite into the shaft to hold it. They are simple and effective for reversing loads but can mar the shaft surface.

An eccentric locking collar (often with an "HC" prefix) is easier to install. You rotate the collar to lock it. However, it tightens with rotation, meaning it is strictly for uni-directional applications. If the motor reverses, the collar may loosen.

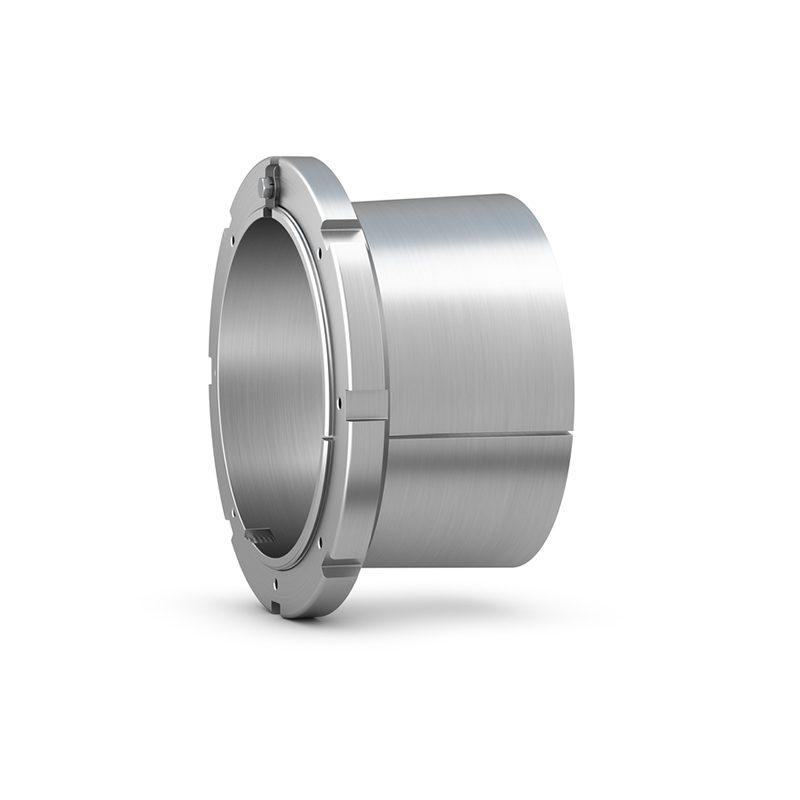

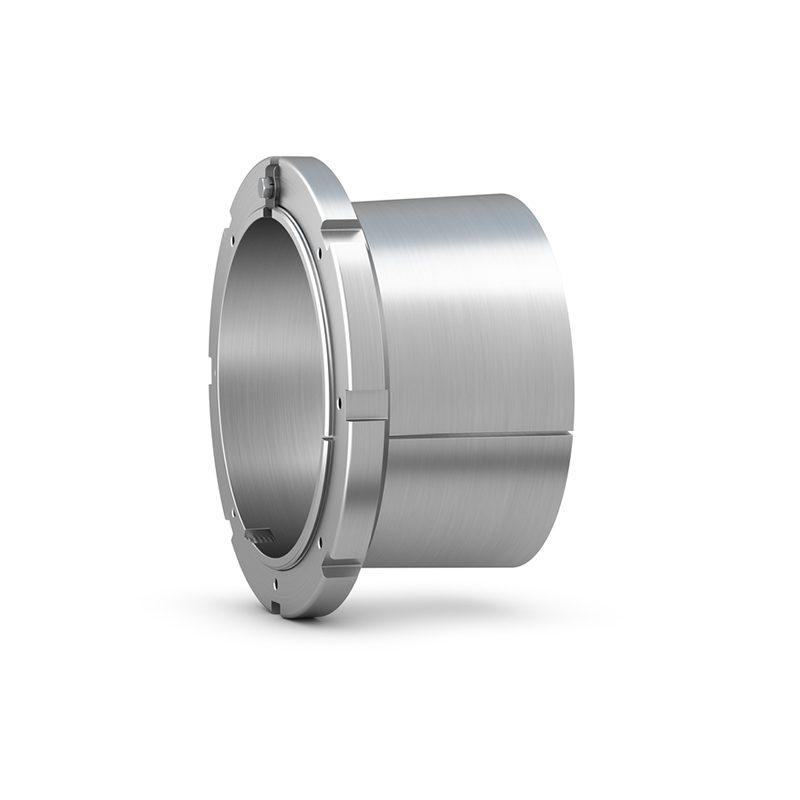

For applications with heavy vibration or undersized shafts, an adapter sleeve is best. This system uses a tapered sleeve to grip the shaft continuously around its circumference, providing excellent concentricity. You will often see this on a UCP206 pillow block bearing used in industrial fans. In some cases, you may need a separate h313 truck bearing adapter sleeve or similar component to ensure a secure fit on specialized equipment.

Strategic Selection Framework (The 5-Step Evaluation)

To avoid premature failure, follow this five-step evaluation process before purchasing your next Pillow Block Bearing.

1. Calculate Loads (Static vs. Dynamic)

Never guess the weight. Calculate the radial and axial forces. Compare these against the bearing's dynamic load rating (Cr). A good engineering practice is to ensure the bearing's rating is 1.5 to 2 times higher than your actual application load. This safety factor accounts for shock loads and unexpected spikes.

2. Determine Speed (RPM) Limits

Bearings generate heat as they spin. The faster they go, the hotter they get. Check the manufacturer's DN value or speed limit tables. Grease lubrication, which is standard in pillow blocks, has a lower speed limit than oil. If you exceed this, the grease degrades, and the bearing seizes.

3. Assess Misalignment Potential

Look at your mounting surface. Is it perfectly flat steel, or is it an uneven concrete floor? If there is a risk of misalignment, you must prioritize self-aligning spherical roller units. Using a rigid ball bearing on a bent frame is a guarantee of early failure.

4. Define the Operating Environment

List the hazards: Temperature extremes, dust, and moisture. Standard seals keep out basic dirt, but fine dust requires triple-lip seals. High heat requires Viton seals. High moisture demands stainless steel or coated inserts. Matching the seal and material to the environment is just as important as matching the load.

5. Evaluate Manufacturer Reliability

Not all bearings are created equal. Low-cost imports may save money upfront but often suffer from inconsistent metallurgy or poor seal quality. When reliability is paramount, choose a reputable Pillow Block Bearing manufacturer that provides full technical data and consistent quality control. Balancing the initial purchase price against the cost of potential downtime is key to smart procurement.

Conclusion

Choosing the right 1-inch pillow block bearing requires more than just a caliper measurement. It demands a holistic view of your equipment's needs. You must ensure dimensional compatibility—checking bolt spacing and center height—while also selecting the right internal insert for your load direction and speed. Furthermore, the housing material must be able to survive your specific operating environment, whether that involves chemical washdowns or outdoor weather exposure.

Taking a Total Cost of Ownership (TCO) perspective changes how you buy. Investing in a specific "Heavy-Duty" or "High-Precision" unit upfront often reduces maintenance intervals and eliminates unplanned shutdowns. Before you order your next replacement, take the time to re-measure your bolt spacing, verify your load requirements, and check your environmental conditions.

FAQ

Q: What is the difference between a UCP205-16 and a UCP206-16?

A: Both units fit a 1-inch shaft (indicated by the "-16"). However, the UCP206 uses a physically larger 206-series housing and bearing insert. This gives the UCP206 a significantly higher load capacity and a larger grease reservoir compared to the standard duty UCP205. They also have different bolt hole spacing and center heights, so they are not directly interchangeable on a fixed mounting base.

Q: Can I replace a cast iron pillow block with a stainless steel one directly?

A: Yes, provided the dimensional footprints (bolt spacing and center height) match. However, you must check the load ratings. Stainless steel is generally softer than cast iron, so a stainless housing may have a slightly lower static load capacity. Ensure the new stainless unit can still handle your application's mechanical forces before switching.

Q: How much misalignment can a standard pillow block bearing handle?

A: Standard deep groove ball bearing inserts can typically handle static misalignment of +/- 2 to 3 degrees. This allows them to compensate for initial mounting errors. However, they are not designed for continuous dynamic misalignment (wobble) while running. For continuous misalignment, a spherical roller bearing is the better choice.

Q: When should I use a high-temperature pillow block bearing?

A: You should switch to a high-temperature unit when operating temperatures consistently exceed 250°F (120°C). Standard grease liquefies and standard rubber seals harden and crack at these temperatures. High-temp units use special Viton or silicon seals, increased internal clearances for thermal expansion, and high-temperature synthetic grease to ensure survival.

Q: What causes pillow block bearings to fail prematurely?

A: The most common causes are improper lubrication (either too little or too much), misalignment during installation (tightening bolts on an uneven surface), and undersized load ratings. Contamination from dust or water entering the seal is also a major factor. Ensuring the correct fit, alignment, and seal type prevents the majority of early failures.

English

English