You can see new changes in the ball bearing industry. These changes help modern equipment work better. Makers now use new alloys, ceramics, and smart technology. This makes ball bearings more reliable and efficient. For example, E-ASIA makes strong bearings. These bearings last longer and work well in hard places. Many companies also use lighter and rust-proof materials. They care about the environment too. The table below shows some new trends:

Trend/Advancement | Description |

Material Innovation | New alloys, ceramics, and coatings help with speed and heavy loads. |

Smart Technology Integration | Sensors and analytics help watch and fix problems early. |

Environmental Sustainability | Eco-friendly choices use less energy and are easier to recycle. |

Key Takeaways

Smart bearings have sensors that check their health. This lets you find problems early. It helps your equipment last longer.

Advanced materials like ceramics and special coatings make bearings tougher. These materials help bearings last longer. Picking the right material can make them work better.

Eco-friendly bearings make less waste and use less energy. Choosing these options helps the planet. They also keep things working well.

Predictive maintenance lets you fix things before they break. This saves time and money. It stops sudden problems from happening.

Custom bearing designs fit special needs in different industries. Making bearings just for your equipment can make them work better. It also makes them more reliable.

Ball Bearing Advancements

Smart Bearings

Smart bearings are now in many machines. They use self-powered technology to check their own condition. These bearings collect data all the time. The data goes to your computer or phone. You can see how the bearing works each day. Here are some main features of smart bearings:

They use energy harvesting like electromagnetic, piezoelectric, thermoelectric, triboelectric, and tribovoltaic generation.

These ways give power to sensors inside the bearing.

The sensors watch temperature, vibration, and speed.

You get alerts if something is wrong.

Smart bearings help your equipment last longer. They make it easy to find problems early. This technology is changing the ball bearing industry. It also brings new chances for growth in the global ball bearing market.

Predictive Maintenance

Predictive maintenance uses smart bearings to look for trouble. You can use the data to plan repairs before things break. This saves you time and money. Here is how predictive maintenance helps:

You get real-time data about your equipment.

Machine learning tools find patterns and guess when a bearing might fail.

You can fix problems early and stop costly shutdowns.

Real-time dashboards help you make better choices.

Did you know? About 90% of surprise machine shutdowns happen because of bearing failures. Using predictive maintenance can lower these shutdowns and help your work.

Premium ball bearings let you wait longer between maintenance without losing trust. You spend less on labor and avoid stopping production. Predictive maintenance also helps you find issues early, so you can act fast and keep your machines running well.

Advanced Materials

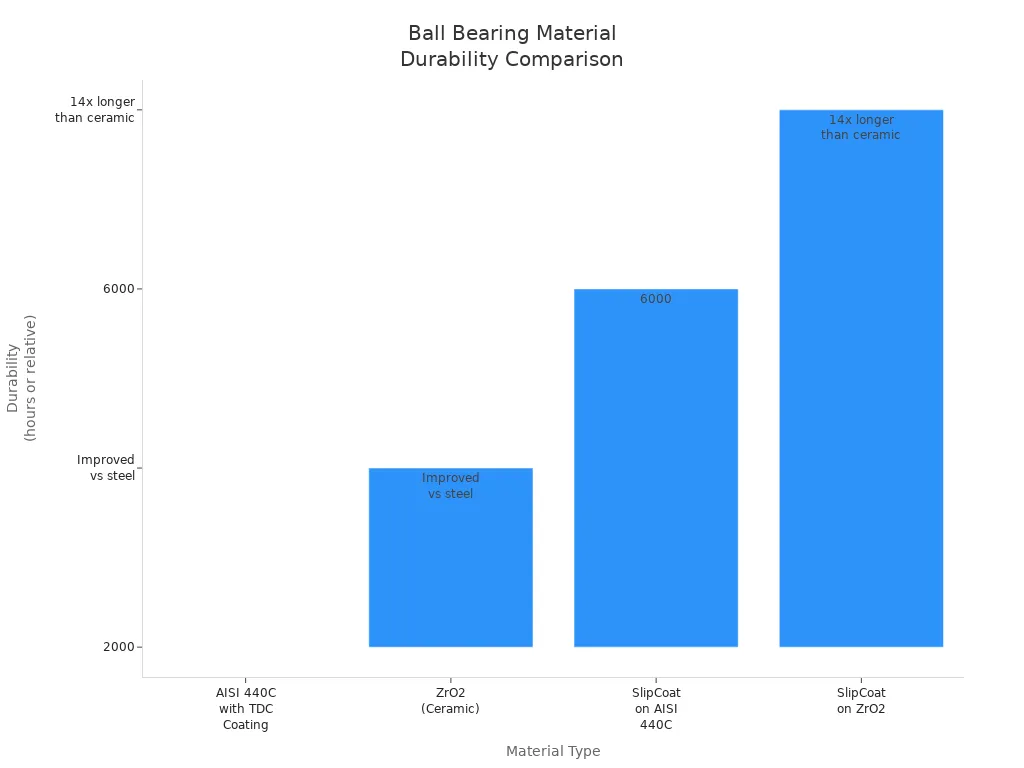

The ball bearing industry now uses advanced materials to make bearings last longer and work better. You can see big improvements in how strong and tough they are. Here is a table showing some of the newest materials and their benefits:

Material | Performance Improvement |

AISI 440C with TDC Coating | High corrosion resistance and durability, lasting over 2000 hours before failure |

ZrO2 (Ceramic) | Better than uncoated steel, but needs extra protection |

SlipCoat on AISI 440C | No visible damage after 6000 hours, showing great longevity |

SlipCoat on ZrO2 | Lasts 14 times longer than untreated ceramic rings |

The material you pick changes how hard and strong your bearings are. For example, 440C stainless steel does not rust easily. M50 tool steel can take high heat and stress. Cobalt-based alloys work well in tough places. E-ASIA Ball Bearing uses top materials for strong design and long life. This makes them a good choice in the global ball bearing market.

Sustainable Solutions

You can help the planet by picking eco-friendly bearings. The ball bearing industry now cares more about the environment. New materials and designs cut waste and save resources. Here are some ways bearings help green practices:

Solid lubricants like graphene and MoS2 lower friction and wear.

Biodegradable lubricants help stop pollution.

Self-lubricating bearings need less care and make less waste.

Regular care also makes bearings last longer, so you replace them less. Many companies recycle old bearings to get back useful materials. The bearing industry works together to set rules for eco-friendly products. These changes help the market grow and protect the earth.

Custom Designs

Custom ball bearing designs fix special problems in many industries. You might need a bearing for heavy loads, high speeds, or tough places. Engineers use new ways to make these bearings. Here is what goes into custom designs:

Special steps like precision grinding or additive manufacturing.

Careful balance between design limits and what you need.

Picking the right material for the job.

E-ASIA Ball Bearing has special options, like thrust and deep groove ball bearings. Deep groove ball bearings are good for radial loads. They do not work as well for thrust loads. Thrust bearings are made for axial loads and do better there. Picking the right type helps your equipment last longer and work better.

Ball bearing market analysis shows custom solutions are wanted. As the ball bearing market grows, you will see more products made for each job. Ball bearing market statistics show a bright future for new ideas and chances in this field.

Ball Bearing Market Trends

Digital Transformation

Digital transformation is changing ball bearings every day. Smart bearings use sensors to check temperature, vibration, and load. These sensors send data to your devices right away. You can see problems before they happen and plan repairs early. This saves you time and money. Many companies use digital tools to work better and make good choices. Smart bearings help you grow your business and keep machines working longer. Ball bearing market analysis shows digital changes lead to new products and custom designs.

Smart bearings with sensors are getting more common.

Digital tools let you watch how things work and find problems fast.

New technology helps you decide quickly and fix things sooner.

Sustainability Focus

There is a big focus on sustainability in ball bearings now. Companies make bearings that last longer and use less energy. Many industries want products that are good for the planet and make less trash. The ball bearing market is growing because people want eco-friendly choices. In Europe, wind energy projects need strong bearings for turbines. In India, new wind power plants need bearings that work well for a long time. Companies that care about the planet and use smart tech do better than others. The ball bearing market size may reach USD 65.1 billion by 2033, showing strong growth.

The European Investment Bank helps wind energy projects, so more bearings are needed.

Renewable energy projects in Asia and Australia need tough bearings.

Bearings that focus on sustainability help companies follow new rules and changes.

Sector Demands

Different industries push ball bearing makers to create new ideas. There is more need for special bearings in cars, planes, and building. Saving energy and caring for the planet are important reasons for this. Electric and hybrid cars need better bearings to work well. The table below shows what different sectors want from ball bearings:

Sector Demand | Description |

Rising Demand for Machinery and Equipment | Good, precise bearings are needed in cars, planes, and building. |

Energy Efficiency and Sustainability | Bearings help save energy by lowering friction. |

Advancements in Technology | Smart bearings find problems and help things work better. |

Shift Towards Electric and Hybrid Vehicles | More bearings are needed for saving fuel and less pollution. |

You get benefits from these changes as the ball bearing market gets bigger. E-ASIA has over 60 years of experience and offers new and custom solutions. Ball bearing market analysis and statistics show the market will keep growing and bring new chances through 2032.

Bearing Industry Innovations

IoT Integration

The Internet of Things (IoT) is changing ball bearings. IoT sensors are inside bearings now. These sensors check temperature, vibration, and speed all the time. You can use this data to find problems early. This helps you fix things before they break. Many companies use IoT to make bearings work better. IoT helps companies grow faster. You can also watch how each bearing works. This makes it easier to take care of big machines. Because of IoT, the bearings market gets new chances and looks stronger.

Self-Lubricating Bearings

Self-lubricating bearings are a big change for ball bearings. You do not need to add oil or grease anymore. These bearings have their own lubrication inside. This keeps them working smoothly. Here are some main benefits:

You spend less money on fixing and labor.

Lubrication lowers friction and saves energy.

Machines run longer without surprise stops.

You also get bearings that last longer. You do not need to replace them as often. These things help you save money and keep your machines working. Ball bearing market analysis shows self-lubricating bearings help companies get more customers. They also make the ball bearing market bigger. Many experts think this trend will be important for a long time.

High-Performance Coatings

High-performance coatings help bearings last longer and work better. You can find coatings like Diamond-Like Carbon (DLC), molybdenum disulfide, and nanocomposite layers. These coatings make bearings stronger and lower friction. For example, ES302 coating is very thin but very hard. It helps stop wear in moving parts. Many industries use these coatings, like aerospace and cars. Ball bearing market analysis and statistics show coatings help the market grow. As things change, you will see more coatings used to make bearings stronger and more reliable.

Ball Bearing Industry Impact on Equipment

Reliability Gains

Modern bearings help your equipment work for a longer time. New materials and smart designs stop sudden breakdowns. Many makers use strong alloys and better lubrication now. These changes help steel bearings last longer in tough places. You also see more bearings with special coatings. These coatings help with high speeds and heavy loads.

Bearings can hold more weight and stay steady in hot or cold weather.

Fast machines use coatings and lubricants to lower friction. This helps each bearing last longer.

Companies like SKF and Timken have new sensorized and micro-bearings. These products make fewer mistakes and last longer than old ones.

You get more time with your machines working and fewer problems. Ball bearing market analysis shows reliability is very important for growth. As the ball bearing market gets bigger, you find more chances to use these strong parts in your equipment.

Efficiency Improvements

Modern bearings help machines use less energy and work better. You see less friction, so your equipment does not waste power.

Low friction lets machines run faster and use less energy.

High rigidity keeps equipment moving straight. You get better results and less downtime.

Lightweight bearings are easy to install and move.

Less noise makes work nicer for everyone.

New designs help machines carry bigger loads and fix small misalignments.

Ball bearing market analysis shows efficiency is a big reason for market size and share. The global ball bearing market outlook shows more growth as companies want to save energy and work better. You see these changes in many industries, like cars and factories.

Maintenance Reduction

You spend less time and money fixing things with advanced bearings. New treatments like carbon nitriding make bearings tougher and harder to wear out.

Bearings made with clean steel and special treatments last longer, even in rough places.

You can choose the best bearing for your pump or motor. You go longer between checks.

Fewer repairs mean your equipment keeps working.

The ball bearing industry keeps finding ways to lower maintenance. Ball bearing market statistics show companies want products that cost less and work more. The global ball bearing market size keeps growing as more people see the benefits. Market trends and outlook both show more need for low-maintenance solutions.

Real-World Applications

Electric Vehicles

Advanced bearings are in every electric vehicle. These bearings help cars, trucks, and bikes run well. Smart bearings have sensors that give you data right away. You can check your vehicle’s health and plan repairs early. The automobile sector uses special bearings for steering and transmissions. These bearings work at high speeds and carry heavy loads. The global ball bearing market grows as electric vehicles need strong parts.

Application Type | Performance Characteristics |

Passenger Cars | Handles high speed and heavy loads well |

Commercial Vehicles | Special bearings for tough jobs |

Two-Wheelers | Light and works efficiently |

Steering Systems | Thrust ball bearings handle axial loads |

Transmissions | Works steady under high axial loads |

Smart Bearings | Gives real-time data and helps with repairs |

Industry 4.0 tools help watch how bearings work. Anticipatory maintenance means fewer breakdowns and more driving time. |

|

Industrial Automation

Bearings are important in automated factories. You find them in motors, gearboxes, and robot arms. Bearings help machines move smoothly and with control. This makes machines faster and more accurate. Less friction and wear means machines last longer. Ball bearing market analysis shows automation needs good bearings. The market gets bigger as more industries use automation. You see bearings in cars, planes, and factories. These places need bearings for tight fits and good production.

Bearings help robot arms move exactly.

They make machines run well and work better.

You find bearings in many industries, making jobs easier.

Renewable Energy

Modern bearings help wind turbines and solar panels work well. You get smooth movement, so there is more energy and less waste. Bearings lower heat loss and help power move better. Asymmetric spherical roller bearings make energy generation more efficient. Each wind turbine bearing handles different jobs and conditions. New ideas in the ball bearing industry make bearings last longer and need less care. The global ball bearing market outlook shows growth in clean energy. You see more chances as the world wants renewable energy.

Bearings help wind turbines work smoothly.

They lower care needs and last longer.

You get better results and more energy from each system.

Aerospace

You need advanced bearings for safe and good flights. Aircraft use hybrid bearings made of ceramic and steel. These bearings last over 15 years in space. They help control planes and spacecraft, keeping them steady. Good bearings stop flight problems and keep people safe. The ball bearing market outlook shows more growth in aerospace as technology gets better. Ball bearing market statistics say safety and reliability are most important. You see more new ideas in the bearings market.

Contribution | Description |

Attitude Control | Bearings keep planes steady while flying. |

Safety | Good bearings stop flight problems and accidents. |

E-ASIA Ball Bearing helps these sectors with strong products. You see their bearings in electric vehicles, factories, wind turbines, and planes. The ball bearing market grows as more industries need reliable solutions. |

|

Big changes are happening in the ball bearing industry. New materials, smart sensors, and AI help your equipment work better. These things make machines stronger and more efficient. The table below shows how these new ideas help you:

Impact Area | Description |

Efficiency | Energy-saving bearings use less power. |

Durability | Strong materials last longer and can take more heat. |

Sustainability | Eco-friendly designs help protect the earth. |

Customization | Mini bearings fit special kinds of machines. |

Advanced Lubrication | Nano-lubricants help bearings last longer. |

AI Integration | AI helps you find problems early and stop breakdowns. |

Using new ball bearing technology helps your business get ready for the future. You will have less downtime and parts that last longer. Look for trends like Industry 4.0, energy-saving designs, and high-precision bearings in the ball bearing market.

FAQ

What are smart bearings and how do they help you?

Smart bearings have sensors inside them. These sensors watch things like heat and shaking. You get a warning if something is wrong. This helps you fix problems before they get worse. Your machines can keep working for a longer time.

Which materials make ball bearings last longer?

Ball bearings are made from many materials. Here is a simple table:

Material | Benefit |

Stainless Steel | Does not rust easily |

Ceramics | Works fast, wears less |

Coated Steel | Stays strong longer |

Pick the best one for your job.

How often should you check or replace ball bearings?

Check your bearings every few months to be safe. If you hear odd sounds or feel them move rough, change them. Smart bearings can tell you the best time to do this.

Where do you use advanced ball bearings?

Advanced ball bearings are in electric cars, wind turbines, robots, and planes. They help machines work well and last longer. You also see them in home appliances and factory equipment.

English

English