A Pillow Block Bearing helps you support a rotating shaft in many types of machines. You will often find this part in places like industrial machinery, agricultural equipment, construction tools, food and beverage processing, and packaging lines. This bearing makes machines run smoothly by holding the shaft steady and reducing friction. You can install it easily, and it works well in many different environments.

Key Takeaways

Pillow block bearings support rotating shafts in various machines, ensuring smooth operation and reducing friction.

Choose the right type of pillow block bearing based on load capacity, speed, and environmental conditions for optimal performance.

Regular maintenance, including lubrication and alignment checks, extends the life of pillow block bearings and prevents costly repairs.

Pillow block bearings come in different materials like cast iron and stainless steel, each suited for specific applications and environments.

Installation is straightforward; ensure proper alignment and secure mounting to maximize the bearing's effectiveness.

Pillow Block Bearing Basics

What Is a Pillow Block Bearing

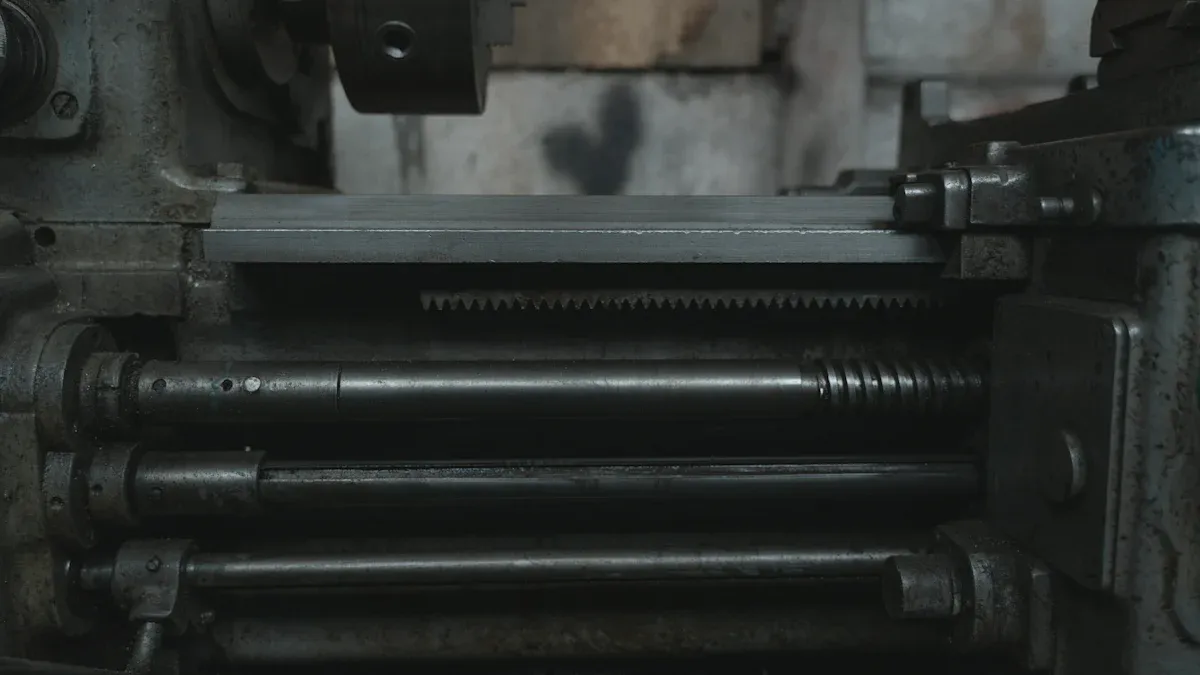

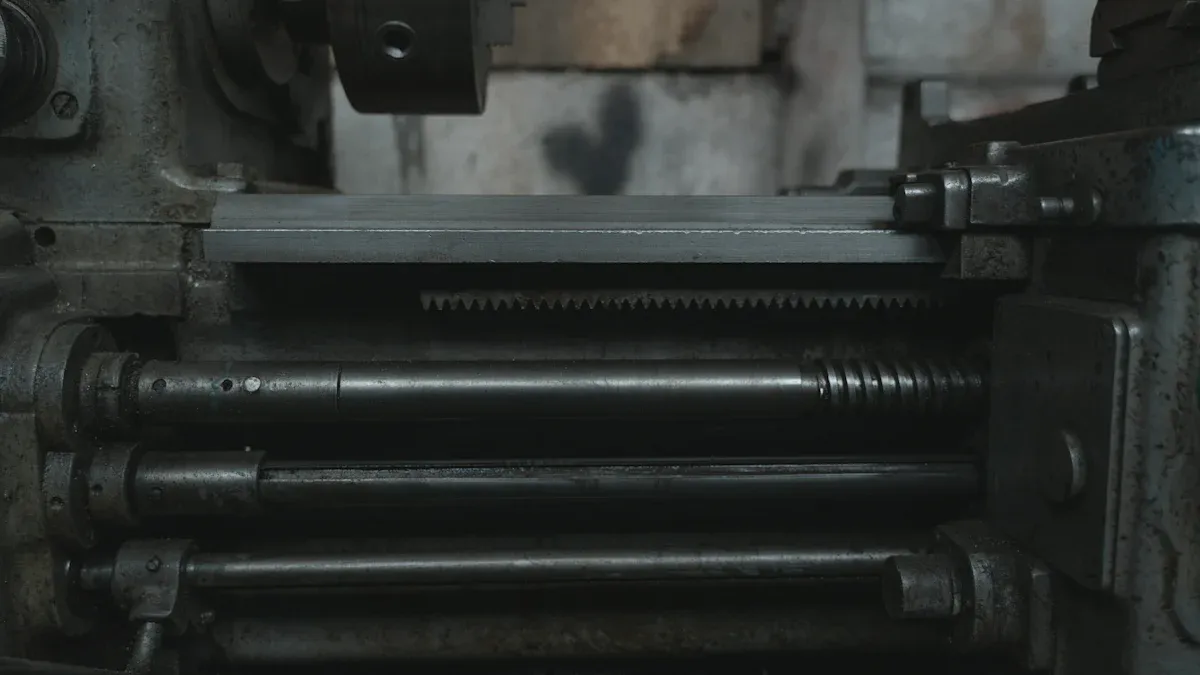

You can think of a pillow block bearing as a special part that helps machines run smoothly. Engineers also call it a plummer block bearing, mounted bearing, or bearing housing. This part holds a bearing inside a strong case, usually made of cast iron or steel. You mount the case on a flat surface, which lets the bearing support a rotating shaft or axle. This setup helps the shaft spin with less friction and keeps it steady.

You will find pillow block bearings in many places. People use them in manufacturing, agriculture, construction, and food processing. These bearings play a key role in material handling and other mechanical systems. When you need to support a spinning shaft, you can count on a pillow block bearing to do the job.

Tip: If you see a machine with a spinning rod or axle, look for a pillow block bearing holding it in place.

Main Components

A pillow block bearing has several important parts. Each part has a special job to do. Here is a table that shows the main components and their functions:

Component | Function |

Bearing Housing | Holds the bearing and gives strong support. |

Bearing | Supports the shaft and lets it spin with little friction. |

Seal | Keeps dirt out and holds in the grease or oil that helps it run smooth. |

You will also notice that the housing or block lets you bolt the bearing to a surface. The inner bearing can be a ball bearing, roller bearing, or another type. Seals and shields protect the inside from dust, dirt, and water. These features help the pillow block bearing last longer and work better in tough places.

When you put all these parts together, you get a strong and reliable way to support a rotating shaft. You can install or replace a pillow block bearing easily, which makes it a popular choice in many machines.

How Pillow Block Bearings Work

Operation and Function

When you look at how a pillow block bearing works, you see a smart design that keeps machines running smoothly. The main job of this bearing is to support a rotating shaft and help it spin with less effort. Inside the housing, you find an inner bearing that can be a ball or roller type. This inner bearing lets the shaft turn easily. The housing holds everything in place and keeps the shaft lined up straight. Seals around the bearing block out dust and dirt, so the inside stays clean and the grease or oil does not leak out.

You get a stable setup because the housing bolts down to a flat surface. This stops the bearing from moving or shaking. When the shaft spins, the bearing reduces friction and helps the machine run quietly. You also notice that this design cuts down on vibrations. That means your machines last longer and need fewer repairs.

Note: Seals play a big role in keeping out water and dirt. This helps your pillow block bearing last longer, even in tough places.

Friction Reduction and Shaft Support

You want your machines to run with as little friction as possible. Pillow block bearings help you do this in several ways:

They give a strong and steady home for the bearing, so the shaft can spin smoothly.

The tough housing lets the bearing handle heavy loads without bending or breaking.

You get a longer life from your bearing compared to many other types.

The design helps you deal with both radial loads (pushing from the side) and axial loads (pushing along the shaft).

You should know that the load capacity depends on the type of bearing, the material, and how you use it. There are two main kinds of loads: radial, which pushes against the shaft from the side, and axial, which pushes along the shaft. You also need to think about static loads, when the machine is not moving, and dynamic loads, when the shaft is spinning.

Here is a quick look at some common types and what they do best:

Type | Best For |

Ball Bearing Pillow Blocks | Self-alignment and general use |

Roller Bearing Pillow Blocks | Heavy-duty jobs with high radial forces |

Stainless Steel Pillow Blocks | Wet or chemical environments |

Cast Iron Pillow Blocks | High strength and shock absorption |

When you pick the right pillow block bearing, you make sure your machine can handle the job. You get smooth rotation, less friction, and strong support for your shaft.

Pillow Block Bearing Applications

Common Uses in Industry

You will see pillow block bearings in many types of machines. These bearings help you keep shafts steady and spinning smoothly. You can find them in places where reliability matters most. Here are some of the most common machines and systems that use pillow block bearings:

Mining equipment

Agricultural machinery

Food processing machines

Conveyor systems

Motors

Heavy-duty machinery

Each of these machines needs strong support for rotating shafts. Pillow block bearings give you that support. You can install them easily, and they work well in tough environments. If you work with conveyor belts or motors, you will notice how these bearings keep everything running without much noise or vibration.

Tip: You can spot pillow block bearings in conveyor systems at factories or farms. They help move products and materials with less effort.

Orientation and Load Capabilities

You need to know how pillow block bearings handle different loads and shaft positions. These bearings can support shafts that run horizontally or vertically. You can use them in machines that need to carry heavy loads or just light ones. The design lets you deal with both radial and axial forces.

Here is a table that shows how pillow block bearings perform in high-load and low-load environments:

Feature | High-Load Environment | Low-Load Environment |

Load Capacity | Designed for substantial loads | Operates efficiently without premature wear |

Construction | Robust construction for demanding applications | Reliable performance in less demanding settings |

Misalignment Accommodation | Self-aligning designs to handle misalignment | Still effective, but less critical in low-load |

You get strong performance from pillow block bearings in industrial machinery, conveyor systems, and agricultural equipment. The bearings often use a high-quality chrome steel insert inside a tough cast iron housing. This setup ensures smooth operation and helps you deal with shaft misalignment.

If you need to support a shaft in a machine, you can trust pillow block bearings to handle the job. They work well in many positions and can take on heavy or light loads. You get reliable support and longer machine life.

Types and Materials

Main Types

You can choose from several main types of pillow block bearings. Each type has a special design for different jobs. The table below shows the most common types and what makes each one unique:

Bearing Type | Description |

UC | Set screw locking bearing, the most common type. |

UK | Tapered bore bearing, used with adapter sleeves. |

HC | Eccentric locking collar, used in agricultural equipment. |

SB | Smaller bore, lightweight bearings. |

SA | Narrow inner ring, used in lighter applications. |

If you need a bearing for heavy-duty work, you might pick a UK or HC type. For lighter jobs, SB and SA types work well. UC bearings fit most general uses. You should match the type to your machine’s needs for the best results.

Tip: Always check the locking method and bore size before you choose a bearing. This helps you avoid problems during installation.

Common Materials

You will find pillow block bearings made from different materials. The material affects how strong, durable, and resistant to corrosion the bearing is. Here is a table that compares the most common materials:

Material Type | Description |

Cast Iron | Available in various models, known for strength and durability. |

Steel | Commonly used for rolling elements and unit bodies. |

Cast iron gives you high strength and lasts a long time. Steel works well for parts that need to roll or move. Stainless steel resists rust and handles tough environments. If you need a bearing for wet or chemical areas, stainless steel is a smart choice.

The material you pick changes how your bearing performs. Strong metals like stainless steel help your bearing survive sudden impacts. Good design, proper lubrication, and heat treatment also make your bearing last longer. You should think about the environment where you will use the bearing. Stainless steel and alloy steel resist corrosion, while aluminum may bend under heavy loads. Some polymers reduce friction and help your machines run smoothly.

Note: The right material helps your Pillow Block Bearing handle heavy loads, resist rust, and run with less friction. This means less maintenance and a longer life for your equipment.

Selection, Installation, and Care

Choosing the Right Pillow Block Bearing

You want your machines to last and work well. To do this, you need to pick the right bearing for your job. Here are some things you should look at:

Load capacity: Make sure the bearing can handle the weight and force from your machine.

Rotational speed: Choose a bearing that works well at the speed your shaft will spin.

Operating environment: Think about temperature, moisture, and chemicals. Some bearings need special materials for tough places.

Mounting: Check the size and shape of your machine. The bearing must fit and bolt down easily.

Tip: Always match the bearing to your machine’s needs. This helps you avoid early breakdowns.

Installation Steps

You can install a pillow block bearing by following these steps:

Gather your tools. You will need a torque wrench, lubricant, mounting bolts, and a clean cloth.

Clean the mounting surface. Make sure it is smooth and free from dirt.

Check the bearing and shaft. Look for any damage or wear.

Put a thin layer of lubricant on the shaft.

Slide the bearing onto the shaft. Line it up straight.

Bolt the bearing down. Tighten the bolts in a crisscross pattern.

Check the alignment again. Adjust if needed.

Add more lubricant to the bearing housing.

Look over your work. Make sure everything sits right and lines up.

Note: Good alignment and clean parts help your bearing last longer.

Maintenance and Troubleshooting

You can keep your bearing working well by following these tips:

Lubricate the bearing at regular times.

Check for wear on the housing, seals, and lock nuts.

Watch for vibration. This can show you if something is wrong.

Inspect the alignment often.

Here is a table of common problems and how you can fix them:

Issue | Solution |

Insufficient Lubrication | Check and add the right lubricant. Keep out dirt and water. |

Shaft Misalignment | Realign the bearing. Make sure the load is even. |

Lubrication Issues | Use the correct type and amount of lubricant. Set a schedule for checks. |

If you take care of your bearings, you can expect them to last for years. Light-duty machines may get 5 to 10 years, while heavy-duty jobs may need new bearings after 1 to 5 years. Regular care means less downtime and smoother machines.

Remember: Clean, lubricate, and check your bearings often. This keeps your machines running and saves you money.

You have learned that a Pillow Block Bearing supports rotating shafts in many machines. The table below highlights key points:

Key Point | Description |

Types | Solid or split housing, with various insert options |

Materials | Aluminum, cast iron, steel, stainless steel, and plastic |

Applications | Used in fast-rotating and heavy-load setups across industries |

Selection | Match load, speed, and environment for best results |

Quality | High-quality bearings prevent costly failures |

Choose the right bearing for your needs.

Install and align it carefully.

Maintain it regularly to extend equipment life and reduce downtime.

Apply this knowledge to improve your machinery’s reliability and efficiency.

FAQ

What is the difference between a pillow block bearing and a plummer block?

You often see both terms used. Pillow block and plummer block both support rotating shafts. Pillow blocks usually have a solid housing. Plummer blocks often have split housings for easier maintenance.

How do you know when to replace a pillow block bearing?

You should replace the bearing if you hear unusual noise, feel vibration, or see visible damage. Regular checks help you spot problems early. Quick action prevents machine failure.

Can you use pillow block bearings outdoors?

Yes, you can use them outdoors. Choose stainless steel or coated bearings for wet or harsh weather. Good seals keep out dirt and water. Regular maintenance helps them last longer.

Do pillow block bearings need lubrication?

Yes, you need to lubricate pillow block bearings. Lubrication reduces friction and wear. Check the manufacturer’s guide for the right type and schedule. Proper care keeps your bearing running smoothly.

How do you align a pillow block bearing?

You align the bearing by placing it on a clean, flat surface. Use a straight edge or laser tool to check alignment. Tighten bolts evenly. Good alignment prevents early wear and keeps your machine running well.

English

English