Introduction

Roller bearings are vital in mechanical systems, helping reduce friction and support heavy loads. These bearings use cylindrical rollers to ensure smooth operation. In this article, we will explore the four main types of roller bearings and their unique applications. By the end, you will understand how to choose the right roller bearing for your needs.

What Are Roller Bearings?

Basic Definition and Function

Roller bearings are mechanical components that reduce friction between moving parts by using cylindrical or needle-shaped rollers instead of balls. This design allows them to handle heavier loads compared to ball bearings. The rollers help distribute the load more evenly, resulting in lower friction, higher efficiency, and extended service life for the bearing. Roller bearings are commonly used in various industries, from automotive to manufacturing and agriculture.

Key Components of Roller Bearings

The main components of a roller bearing include:

● Inner Ring: The ring that fits on the shaft and rotates with it.

● Outer Ring: The stationary ring that is mounted in the housing.

● Rollers: Cylindrical, needle, or tapered rollers that provide load-bearing support.

● Cage: A separator that holds the rollers in place, preventing them from contacting each other.

● Seal: A component that protects the bearing from contaminants and retains lubrication.

The Four Types of Roller Bearings

Cylindrical Roller Bearings

Cylindrical roller bearings are characterized by their cylindrical rollers that provide a large contact area, allowing them to handle heavy radial loads. They are ideal for high-speed applications and are commonly used in gearboxes, conveyors, and motors. These bearings come in different variations, including single-row and multi-row designs. The multi-row design offers enhanced load-carrying capacity, making it suitable for demanding applications.

Needle Roller Bearings

Needle roller bearings feature long, thin rollers with a small diameter, making them ideal for applications where space is limited. Despite their compact size, they can carry heavy radial loads. Needle roller bearings are widely used in automotive transmissions, domestic appliances, and electric motors. Their slim profile allows them to fit into tight spaces while maintaining high load-carrying capacity.

Spherical Roller Bearings

Spherical roller bearings are designed to handle both radial and axial loads. They are equipped with spherical-shaped rollers that can accommodate misalignments, making them perfect for applications where shaft deflection or misalignment is a concern. These bearings are commonly used in industrial machinery, construction equipment, and heavy-duty applications, where both high load capacity and the ability to tolerate misalignment are essential.

Tapered Roller Bearings

Tapered roller bearings have a unique design with conical rollers that allow them to handle both radial and thrust loads. This makes them suitable for applications such as automotive wheel hubs, gearboxes, and high-load industrial machinery. Tapered roller bearings are commonly used in situations where high radial load and axial load need to be supported simultaneously.

Bearing Type | Roller Shape | Load Type | Special Feature | Typical Applications |

Cylindrical Roller Bearing | Cylinder | Radial | High radial load capacity | Gearboxes, heavy machinery |

Needle Roller Bearing | Needle | Radial | Compact for space-limited areas | Automotive transmissions, motors |

Spherical Roller Bearing | Barrel | Radial & Axial | Self-aligning, handles misalignment | Industrial fans, construction equipment |

Tapered Roller Bearing | Cone | Radial & Thrust | Can handle combined loads, adjustable | Automotive, heavy-duty machinery |

Applications of Roller Bearings

Roller bearings are used in a wide range of applications across various industries. In the automotive sector, roller bearings are used in engines, transmissions, and wheel hubs to reduce friction and ensure smooth movement. Industrial machinery, such as pumps, conveyors, and gearboxes, relies on roller bearings to support heavy loads and improve efficiency. Additionally, roller bearings play a crucial role in medical equipment, household appliances, and agricultural machinery, providing durability and high performance under diverse conditions.

Automotive and Industrial Machinery

Roller bearings are vital components in the automotive industry, used in various parts like wheels, transmissions, and engines. They are also essential in industrial machinery, such as conveyors, fans, and pumps, where they help support heavy loads and ensure smooth operation.

Household and Medical Equipment

In household appliances like washing machines and refrigerators, roller bearings contribute to smooth and quiet operation. They are also used in medical equipment such as MRI machines and X-ray machines, where precision and reliability are critical.

Agriculture and Construction

Roller bearings are commonly found in agricultural machinery, such as tractors and harvesters, where they support heavy loads and provide long-lasting performance. Similarly, in construction equipment like bulldozers and cranes, roller bearings help maintain stability and handle heavy loads.

Industry | Bearing Types Used | Example Applications |

Automotive | Cylindrical, Tapered, Needle | Gearboxes, wheels, transmissions |

Industrial Machinery | Cylindrical, Spherical, Tapered | Conveyors, pumps, fans |

Household & Medical | Needle, Cylindrical | Washing machines, MRI machines |

Agriculture & Construction | Spherical, Tapered, Cylindrical | Tractors, excavators, cranes |

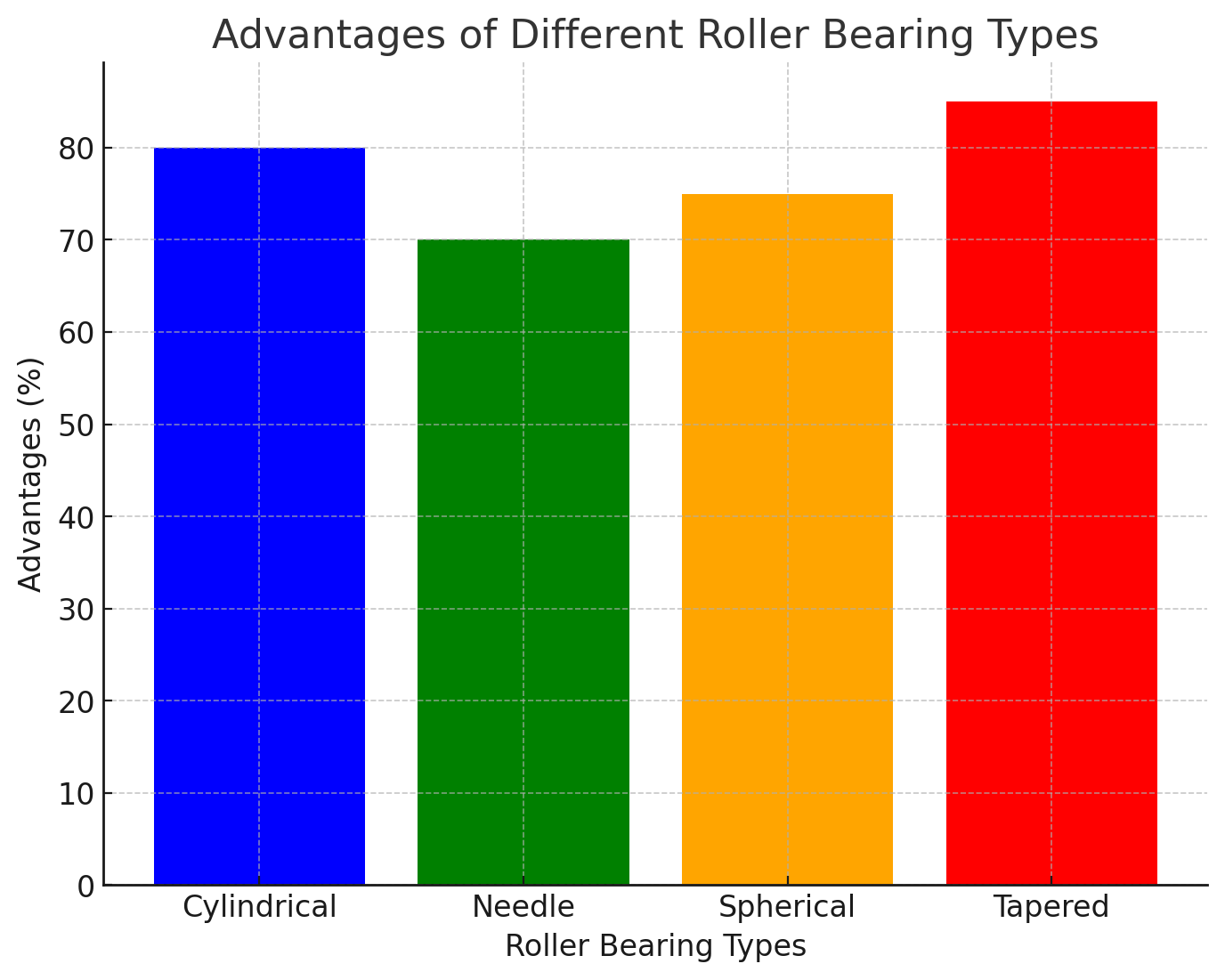

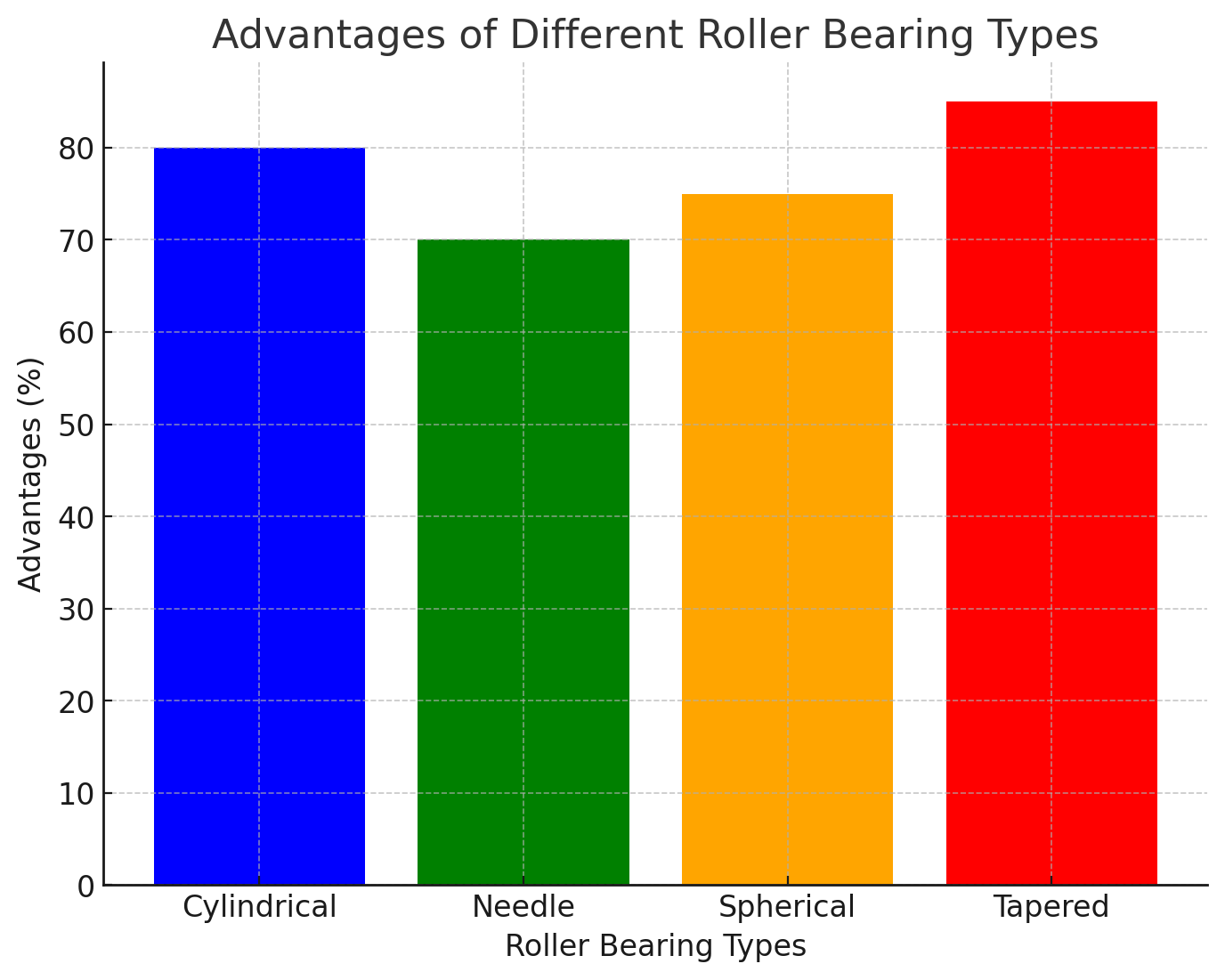

Comparing the Four Types of Roller Bearings

Load Capacity Comparison

Each type of roller bearing is designed to handle different load capacities. Cylindrical roller bearings excel in supporting radial loads, while spherical roller bearings can handle both radial and axial loads. Needle roller bearings, with their compact design, provide high load capacity in tight spaces, while tapered roller bearings are ideal for handling both radial and thrust loads.

Speed and Durability

Cylindrical roller bearings are well-suited for high-speed applications, while needle roller bearings offer excellent performance in confined spaces. Spherical roller bearings are durable and can tolerate misalignments, making them perfect for heavy-duty applications. Tapered roller bearings are versatile and can handle both radial and axial loads at moderate speeds.

Cost Considerations

The cost of roller bearings can vary depending on their type and application. Generally, needle roller bearings are more cost-effective due to their simple design and space-saving capabilities. However, spherical and tapered roller bearings tend to be more expensive due to their robust construction and ability to handle complex load conditions.

Bearing Type | Radial Load | Axial Load | Max Speed | Notes |

Cylindrical Roller Bearing | High | Low | Moderate | Suitable for heavy radial loads |

Needle Roller Bearing | High | Low | Moderate | Ideal for tight spaces |

Spherical Roller Bearing | High | Moderate | Moderate | Handles misalignment |

Tapered Roller Bearing | High | High | Moderate | Supports combined loads |

Advantages and Disadvantages of Roller Bearings

Benefits of Roller Bearings

Roller bearings offer numerous advantages, including:

● Increased Load Capacity: They can carry heavier loads compared to ball bearings.

● Durability: Roller bearings are designed to last longer, even under harsh operating conditions.

● Efficiency: They reduce friction, which helps improve the overall efficiency of machinery.

Limitations of Roller Bearings

However, roller bearings also have some drawbacks:

● Lower Speed Capability: Roller bearings generally operate at lower speeds compared to ball bearings.

● Higher Friction: The increased surface contact in roller bearings can generate more friction, which may require better lubrication and maintenance.

Selecting the Right Roller Bearing for Your Application

Key Factors to Consider

When selecting the right roller bearing, it is essential to consider factors such as load capacity, speed, and the operating environment. For high-load applications, spherical or tapered roller bearings may be more suitable, while needle roller bearings are ideal for space-constrained environments.

Best Practices for Choosing Roller Bearings

To ensure the optimal performance of roller bearings, it is important to choose the right bearing based on the specific requirements of your application. Regular maintenance, proper lubrication, and correct installation are key to extending the service life of roller bearings.

Conclusion

Roller bearings are essential for reducing friction and supporting heavy loads in various applications. The four main types—cylindrical, needle, spherical, and tapered roller bearings—each offer distinct advantages for specific uses. By understanding these differences, you can choose the right roller bearing for your needs. EASIA bearings provides durable and reliable solutions, tailored to meet your industrial requirements.

FAQ

Q: What are roller bearings used for?

A: Roller bearings are used to reduce friction and support heavy loads in various machinery, including automotive, industrial, and agricultural applications.

Q: What is the difference between roller bearings and ball bearings?

A: Roller bearings use cylindrical rollers to support loads, while ball bearings use spherical balls. Roller bearings are better for handling heavier loads but are slower than ball bearings.

Q: How do cylindrical roller bearings work?

A: Cylindrical roller bearings use cylindrical-shaped rollers that are in linear contact with the raceways, allowing them to carry heavy radial loads efficiently.

Q: Can needle roller bearings handle heavy loads?

A: Yes, needle roller bearings can handle heavy radial loads while being compact, making them ideal for applications with space constraints.

Q: Where are spherical roller bearings commonly used?

A: Spherical roller bearings are commonly used in machinery where misalignment or axial load handling is required, such as in industrial fans and construction equipment.

Q: What are the key benefits of tapered roller bearings?

A: Tapered roller bearings can handle both radial and thrust loads, making them suitable for applications in automotive transmissions and heavy-duty machinery.

English

English