Roller bearings are an essential component in various industrial applications, providing support for rotating shafts and reducing friction between moving parts. These bearings are widely used in industries such as automotive, aerospace, manufacturing, and heavy machinery. The roller bearing's primary function is to carry heavy loads and allow for smooth rotational movement, making it a critical element in the efficient operation of many machines. This research paper delves into the different types of roller bearings, their applications, and the factors that influence their performance. Additionally, we will explore the significance of roller bearing application in various industries and how advancements in technology have enhanced their functionality.

Roller bearings are designed to handle both radial and axial loads, making them versatile for numerous applications. The ability to reduce friction and wear between moving parts ensures the longevity of machinery and equipment. As industries continue to evolve, the demand for more efficient and durable roller bearings has increased. In this paper, we will examine the key aspects of roller bearing application and its role in improving operational efficiency across different sectors.

In the following sections, we will discuss the various types of roller bearings, their specific uses, and the factors that affect their performance. We will also highlight the importance of selecting the right roller bearing for a particular application to ensure optimal performance and longevity. By understanding the principles of roller bearing operation and their applications, industries can make informed decisions that lead to improved productivity and reduced maintenance costs. For more information on the various industries that utilize roller bearings, visit the roller bearing application page.

Types of Roller Bearings

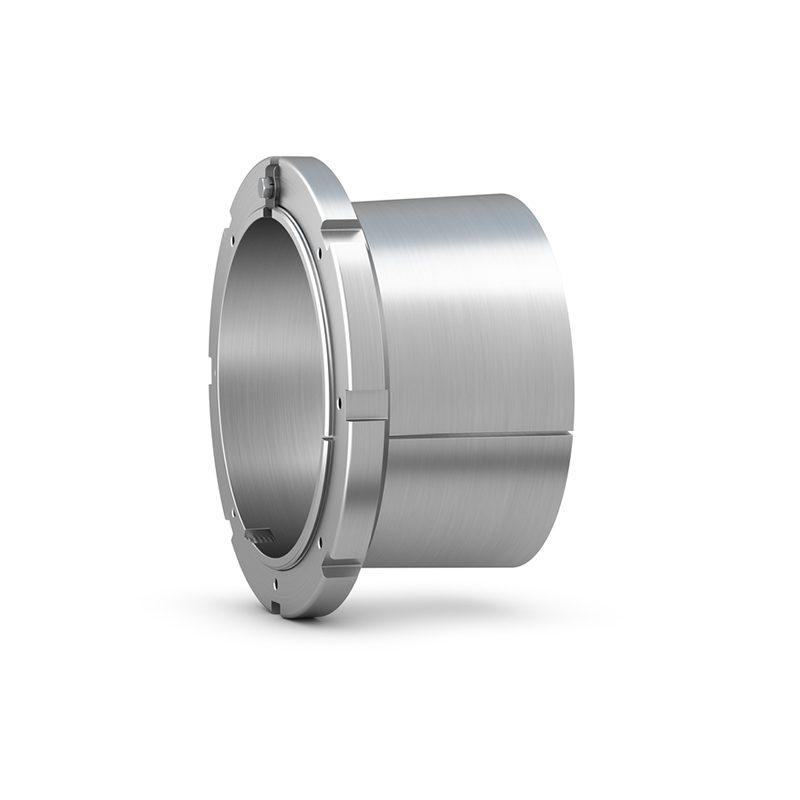

Roller bearings come in various types, each designed for specific applications and load requirements. The most common types of roller bearings include cylindrical roller bearings, spherical roller bearings, tapered roller bearings, and needle roller bearings. Each type has unique characteristics that make it suitable for different applications.

Cylindrical Roller Bearings

Cylindrical roller bearings are designed to handle high radial loads and are commonly used in applications where axial loads are minimal. These bearings are ideal for high-speed applications and provide excellent performance in environments with heavy radial loads. Cylindrical roller bearings are often used in electric motors, gearboxes, and machine tools. Their ability to accommodate misalignment and reduce friction makes them a popular choice in various industries.

Spherical Roller Bearings

Spherical roller bearings are designed to handle both radial and axial loads, making them suitable for applications where misalignment may occur. These bearings are commonly used in heavy machinery, such as mining equipment, construction vehicles, and industrial gearboxes. The spherical shape of the rollers allows for self-alignment, which helps reduce stress on the bearing and prolongs its lifespan. Spherical roller bearings are known for their durability and ability to withstand harsh operating conditions.

Tapered Roller Bearings

Tapered roller bearings are designed to handle both radial and axial loads, with the ability to support higher axial loads than other types of roller bearings. These bearings are commonly used in automotive applications, such as wheel hubs, as well as in heavy machinery and industrial equipment. The tapered design of the rollers allows for better load distribution, which reduces wear and extends the bearing's lifespan. Tapered roller bearings are also known for their ability to handle shock loads and high-speed applications.

Needle Roller Bearings

Needle roller bearings are characterized by their small, cylindrical rollers, which allow them to handle high radial loads in a compact design. These bearings are commonly used in applications where space is limited, such as in automotive transmissions, pumps, and compressors. Needle roller bearings provide excellent performance in high-load, low-speed applications and are known for their ability to reduce friction and wear in tight spaces. Their compact design makes them ideal for applications where weight and space are critical factors.

Factors Affecting Roller Bearing Performance

Several factors can influence the performance of roller bearings, including load capacity, lubrication, alignment, and operating conditions. Understanding these factors is crucial for selecting the right bearing for a specific application and ensuring optimal performance.

Load Capacity

The load capacity of a roller bearing is one of the most critical factors in determining its performance. Bearings are designed to handle specific radial and axial loads, and exceeding these limits can lead to premature failure. It is essential to select a bearing with the appropriate load capacity for the application to ensure long-term reliability. For more information on load capacity and other technical specifications, visit the roller bearing application page.

Lubrication

Proper lubrication is essential for reducing friction and wear in roller bearings. Lubricants help minimize metal-to-metal contact, which can lead to heat buildup and premature wear. The type of lubricant used, as well as the frequency of lubrication, can significantly impact the bearing's performance and lifespan. In high-speed applications, synthetic lubricants are often preferred due to their ability to withstand extreme temperatures and reduce friction.

Alignment

Misalignment can have a significant impact on the performance of roller bearings. Bearings that are not properly aligned can experience uneven load distribution, leading to increased wear and reduced lifespan. Spherical roller bearings are designed to accommodate misalignment, making them ideal for applications where alignment is a concern. Ensuring proper alignment during installation and maintenance is crucial for maximizing the performance and longevity of roller bearings.

Operating Conditions

The operating conditions in which a roller bearing is used can significantly affect its performance. Factors such as temperature, humidity, and exposure to contaminants can all impact the bearing's lifespan. Bearings used in harsh environments, such as mining or construction, must be designed to withstand extreme conditions. Sealed or shielded bearings are often used in these applications to protect against contaminants and ensure reliable performance.

Applications of Roller Bearings

Roller bearings are used in a wide range of industries and applications, from automotive and aerospace to manufacturing and heavy machinery. Their ability to handle heavy loads and reduce friction makes them an essential component in many types of equipment. Below are some of the most common applications of roller bearings:

Automotive: Wheel hubs, transmissions, and differentials

Aerospace: Jet engines, landing gear, and control systems

Manufacturing: Conveyor systems, gearboxes, and machine tools

Heavy Machinery: Mining equipment, construction vehicles, and industrial gearboxes

Energy: Wind turbines, hydroelectric generators, and power transmission systems

Each of these applications requires specific types of roller bearings to ensure optimal performance and reliability. For example, tapered roller bearings are commonly used in automotive applications due to their ability to handle both radial and axial loads. In contrast, spherical roller bearings are often used in heavy machinery and industrial gearboxes due to their durability and ability to accommodate misalignment. For more information on specific applications, visit the roller bearing application page.

Conclusion

In conclusion, roller bearings play a vital role in various industries by providing support for rotating shafts and reducing friction between moving parts. The different types of roller bearings, such as cylindrical, spherical, tapered, and needle roller bearings, each have unique characteristics that make them suitable for specific applications. Understanding the factors that affect roller bearing performance, such as load capacity, lubrication, alignment, and operating conditions, is crucial for selecting the right bearing for a particular application.

As industries continue to evolve, the demand for more efficient and durable roller bearings will increase. By selecting the appropriate bearing for each application and ensuring proper maintenance, industries can improve operational efficiency, reduce downtime, and extend the lifespan of their equipment. For more detailed information on roller bearing applications and their role in various industries, visit the roller bearing application page.

English

English