Early problem detection helps your ball bearing work well. You can find issues by listening for strange sounds. You can also feel if there is too much shaking. Studies show that 30% to 50% of machine failures are from bearing problems. Doing regular checkups helps you stop these problems. The table below shows how good care lowers failures. It also helps bearings last longer. Use these tips from E-ASIA to keep your bearings working.

Evidence Type | Statistic | Description |

Failed Bearings | 30-35% | Good storage, handling, and maintenance stop many failures. |

Lubrication Issues | Up to 50% | Using the right lubrication fixes almost half of bearing problems. |

L10 Life Calculation | 90% | Many bearings do not last as long as they should. |

Key Takeaways

Listen for odd sounds and feel for shaking to find ball bearing problems early. Regular checks and using the right oil can stop half of bearing failures. Use the correct oil and stick to a plan to keep bearings working well. Watch for dirty grease or rust to stop bearings from breaking too soon. Ask an expert if you see strange heat, noise, or problems with your bearings.

Ball Bearing Problem Signs

Common Warning Signs

You can find ball bearing problems if you know what to check. Machines show clear signs when bearings start to fail. Here are the most common warning signs in factories:

Too much or strange noise. You might hear grinding, squeaking, or clicking. These sounds often mean the bearing needs more lubrication or has a problem.

Vibrations. If you feel shaking or see the machine vibrate more, it can mean the bearings are not lined up right or are damaged.

Too much heat. If a bearing gets hotter than normal, friction is building up. This can make the bearing wear out faster and break.

Lubricant leaking. If you see oil or grease coming out, the bearing might be damaged. Leaks make the bearing wear out faster and not last as long.

Slow or stuck movement. If the machine moves slowly or feels stuck, the bearing could be worn out or broken.

Tip: Check for these warning signs when you do regular inspections. Finding problems early helps you avoid expensive repairs and keeps your machines working well.

Inspection Tools

You can use different tools to find bearing problems before they get worse. Vibration analysis is a good way to check. This tool measures vibration from moving machines. It helps you find tiny defects early. As problems get bigger, vibration changes, so you can plan repairs and stop big failures. Checking temperature also helps you find friction problems. If you see the temperature go up, check the bearing right away.

Finding problems early helps your machines work better. Vibration checks and temperature checks help you stop surprise breakdowns. These tools help you save time and money on repairs. Use them to keep your bearings working and your factory running.

Note: Using inspection tools often helps you find problems before they get bad. You can stop sudden failures and help your ball bearings last longer.

Lubrication Issues in Bearings

Identifying Lubrication Issues

You can find lubrication problems if you know what to check. Many bearing problems start when there is not enough lubrication. If you hear grinding or see extra heat, there may be a problem. Sometimes, oil or grease leaks out of the bearing. This means the lubricant is not working well. You might notice slow movement or roughness when you turn the ball bearing. These signs show your bearings need help.

Tip: Check for leaks, strange sounds, or extra heat during inspections. Acting early helps you stop bearing problems and keeps your bearings working well.

Causes of Lubrication Failure

Lubrication failure happens for many reasons. Most times, people use the wrong lubricant or not enough. Studies say about 80% of bearing failures come from bad lubrication. Other reasons are picking the wrong bearing or mounting it wrong. Problems with the automatic lubrication system also cause trouble. Sometimes, people forget to add lubricant or use the wrong schedule. These mistakes make the lubrication weak and damage the bearing.

Here are the main causes:

Using the wrong lubricant for your bearings

Not enough lubricant in the bearing

Skipping lubrication intervals

Problems with the automatic lubrication system

Poor bearing selection or mounting

Solutions for Lubrication Problems

You can fix lubrication problems with easy steps. First, pick the right lubricant for your bearings. Deep groove ball bearings work best with general-purpose grease. Thrust bearings need high-quality mineral oils. Heavy-duty bearings do better with synthetic oils. Grease lubricants protect most bearings and last longer. Solid lubricants help in tough places, like high heat or radiation. If you use an automatic lubrication system, check it often to make sure it works.

Follow these steps for better results:

Pick lubricants that match your bearing’s temperature range and load.

Use the right amount of lubricant to avoid insufficient lubrication.

Set up a regular schedule for your automatic lubrication system.

Inspect your bearings often for signs of lubrication failure.

Replace or repair the automatic lubrication system if you find problems.

Note: Good lubrication keeps your bearings safe and helps you avoid bearing problems. Regular checks and the right steps make your bearings last longer.

Contamination in Ball Bearings

Signs of Contamination

You can find contamination if you know what to check. Dirty bearings make grinding or scratching sounds. You might see dark or gritty grease near the bearing. Sometimes, rust or small pits show up on the surface. These signs mean dirt, water, or other things got inside the bearing. If the bearing feels rough when you turn it, it is probably contaminated. Almost half of bearing failures happen because of particles.

Tip: Look for strange sounds, rough movement, or dirty grease every time you inspect. Acting early helps you stop common bearing problems.

Sources of Contaminants

There are many ways bearings get contaminated in factories. The most common are dirty lubricants, water, and dust. Dirty lubrication makes bearings wear out faster. Water in oils can cause marks and rust, which makes bearings weaker. Chemicals or salt in the air can also cause rust.

Other sources are:

Using the wrong lubricant

Dust or debris getting inside

Bearings not lined up right

Rust from water

Damage from electricity

Too much weight

Installing bearings the wrong way

If you do not fix these problems, contamination can make bearings fail early and cost more to repair.

Cleaning and Prevention

You can clean and protect your bearings in different ways. Pick the best cleaning method for your needs. Here is a table with good cleaning methods:

Cleaning Method | Description |

Detergent Washing | Cleans away dirt you can see and dirt you cannot see. |

Chemical Decontamination | Uses special liquids to kill germs and bacteria. |

Ultrasonic Cleaning | Makes bearings extra clean, good for medical uses. |

Sterilization (Steam, Dry Heat) | Kills all germs, making bearings safe for medical use. |

Regular Testing | Checks for dirt with tests to make sure everything is clean. |

To stop rust and keep bearings safe, always use clean lubricants and store bearings in dry places. Seal bearings to keep out water and dust. Check for rust often and change broken seals right away. These steps help you avoid contamination and make your ball bearings last longer.

Note: Clean bearings and good lubrication help stop rust and failure. Make these steps part of your regular care routine.

Bearing Misalignment

Misalignment Symptoms

You can spot bearing misalignment by watching for several clear signs. Machines often show these symptoms when bearings do not line up right. Here are the most common symptoms you might notice:

Vibration increases. Machines shake more because uneven forces act on the parts.

Noise levels rise. You may hear grinding or rubbing sounds as components touch each other.

Heat builds up. Extra friction causes the bearing to get hotter than normal.

Parts wear out faster. Misalignment puts more stress on the bearing, so it wears down quickly.

Efficiency drops. The machine uses more energy and does not work as well.

Tip: If you notice any of these symptoms, check your bearings right away. Early action helps you avoid bigger problems.

Causes of Misalignment

Several things can cause bearing misalignment in your equipment. You might see two main types:

Offset misalignment happens when the centerlines of two shafts stay parallel but do not meet at the power transfer point.

Angular misalignment occurs when the centerlines cross at the power transfer point but do not stay parallel.

Both types can shorten the life of your bearings and lower how well your machine works. Static misalignment often comes from uneven mounting surfaces or bearings that are not set up right. Dynamic misalignment can happen during operation, such as when a shaft bends.

Correction Steps

You can fix bearing misalignment by following a step-by-step process. Here is a simple guide:

Gather your tools and check the machine’s alignment specifications.

Prepare the work area. Lock out the machine, clean the space, and inspect all parts for looseness.

Measure alignment. Check for thermal growth and take initial measurements. Look for soft foot conditions.

Adjust the alignment. Use your measurements to make changes and bring the bearings into the correct position.

Tighten bolts and do a final check to make sure everything lines up.

Write down what you did. Good records help you in the future.

Test the machine. Run it and check that the alignment stays within the manufacturer’s range.

Note: Always measure alignment during installation. This step helps your ball bearing and other bearings work better and last longer.

Bearing Overload and Failure

Detecting Overload Damage

You can find overload damage by looking for certain signs. If a bearing is overloaded, you might see cone bore contraction. This happens when there is too much preload or overload. Heavy loads and high heat can cause full race width fatigue spalling. Both the inner and outer raceway can show even deformation from too much axial load. Too much radial load can make the inner raceway deform evenly. You may notice a "load zone" at the pinch point on the outer raceway. Craters can form on the raceway surface. These craters cause more vibration and heat. If you see these signs, your bearing could fail soon. Finding problems early helps you stop bigger issues. It also keeps your equipment working well.

Causes of Bearing Failure

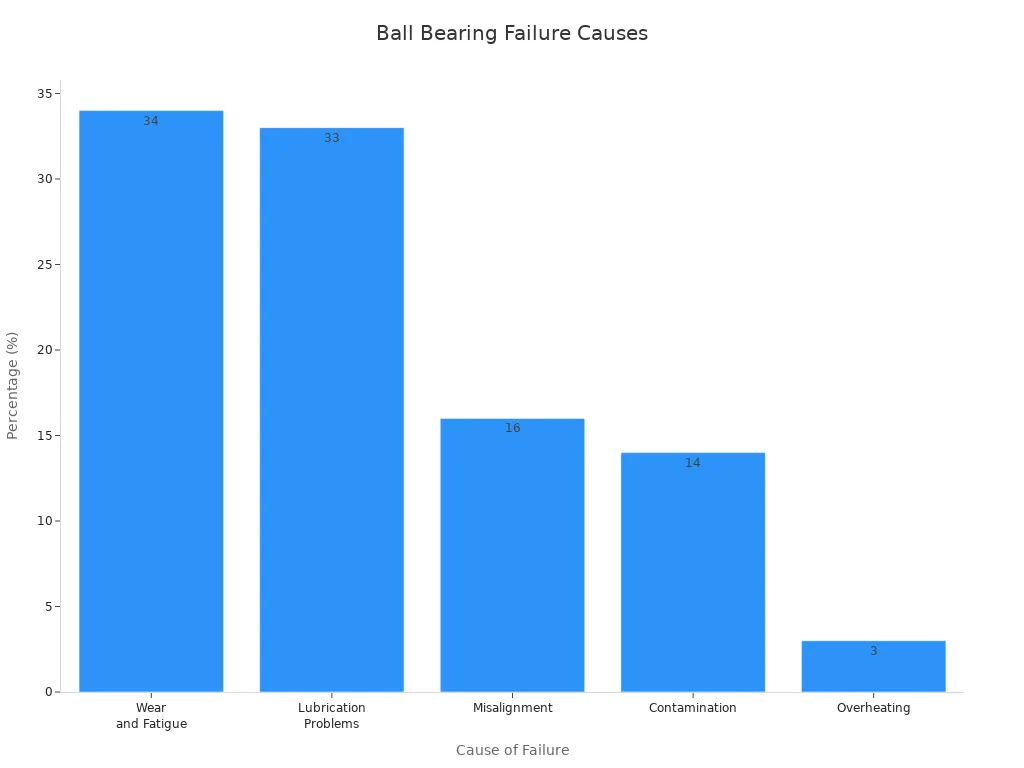

Many things can make bearings fail in machines. The most common causes are wear, lubrication problems, misalignment, contamination, and overheating. The table below shows how often each cause happens:

Cause of Failure | Percentage (%) |

Wear and Fatigue | 34 |

Lubrication Problems | 33 |

Misalignment | 16 |

Contamination | 14 |

Overheating | 3 |

Lubrication problems and wear are the biggest reasons bearings fail. If you do not fix these problems, your bearings can break suddenly. This can lead to expensive repairs.

Prevention and Solutions

You can stop bearing failure by using smart solutions. Use the right lubricant to protect bearings from wear and heat. Check and watch your bearings often to find problems early. Make sure bearings are lined up and balanced when you install them. Keep dirt and other things away from bearing surfaces. Install bearings the correct way to avoid misalignment and overload. Watch the loads on your bearings to prevent overload. Use predictive maintenance tools to plan repairs before bearings fail.

Strategy | Description |

Proper Lubrication | Use the right type and amount of lubricant to prevent wear and overheating. |

Regular Inspection and Monitoring | Find issues early and stop bearing failure before it starts. |

Alignment and Balancing | Reduce stress on bearings by installing them correctly. |

Contamination Control | Keep dirt and debris away from bearing surfaces. |

Proper Installation Techniques | Install bearings the right way to avoid misalignment and overload. |

Load Management | Watch and control the loads on your bearings. |

Predictive Maintenance Technologies | Use advanced tools to predict and prevent bearing failures. |

Tip: Good lubrication covers contact surfaces and lowers friction. It moves heat away and stops rust. Too much or too little lubrication can make bearings fail. Always follow the right schedule.

Installation Errors in Bearings

Installation Mistakes

Knowing about common mistakes can help you stop problems. About 16% of early bearing failures are from bad fitting. These failures often happen because of errors during installation. Here are mistakes you should look out for:

Using the wrong shaft fit can make the bearing slip or wear out fast.

If you tighten the locking device too much, it can hurt the bearing and make it not last long.

Not lining up the bearing right means it will not work well.

Bolts that are loose or not even can make the machine shake and stress the bearings.

If you forget to add lubricant, the bearing will wear out sooner.

Tip: Try not to make these mistakes. This helps your ball bearing last longer and work better.

Error Symptoms

You can find installation errors by watching for some signs. Bearings put in wrong often show these problems:

Strange noise or shaking when the machine runs

Too much heat near the bearing

The bearing surface wears out or gets damaged quickly

Bearings feel loose or move after you put them in

Lubricant leaks out or there are dry spots

If you see any of these signs, check how you installed the bearing. Finding problems early lets you fix them before they get worse.

Correct Installation Steps

You can use good steps to install bearings the right way. Here is an easy guide:

Get ready by cleaning your work area. Take away water, dust, or dirt. Look at the shaft and housing for damage. Check new bearings for dirt or damage. Gather tools like bearing heaters and torque wrenches.

When you put in the bearing cold, line it up and use a fitting tool. Push only on the inner ring. For hot mounting, heat the bearing to 80–100°C, slide it on the shaft, and let it cool down.

After you finish, spin the shaft to see if it turns smoothly. Check the bearing’s temperature after the first run. Add more lubricant if you need to.

Note: Doing these steps helps you avoid mistakes and keeps your bearings working well.

Environmental Impact on Bearings

Temperature and Moisture Effects

It is important to watch temperature and moisture near your bearings. High heat can break down lubricants fast. Lubricants do not work well when it gets too hot. If the temperature goes above 70°C, lubricant life gets much shorter. Every 15°C rise cuts the life in half. Cold temperatures make lubricants thick and hard to move. This causes more force and skidding. Both hot and cold can hurt seals and cages inside the bearing. Moisture can cause rust and change the shape of seals. The table below shows how different temperatures can hurt your bearings:

Temperature Condition | Potential Issues |

High Temperature | - Lubricant does not last as long |

| - Lubricant gets thin and bearings wear out |

| - Raceway gets soft and wears out |

| - Seals dry out and crack, so lubricant leaks |

| - Cage gets weak and can break |

| - Rings grow and change shape, causing wear |

Low Temperature | - Lubricant gets thick and hard to move |

| - Seals get stiff and break |

| - Cage gets brittle and can break |

Tip: Always check temperature and moisture near your bearings. This helps you find problems early.

Environmental Damage Signs

You can find damage from the environment if you know what to look for. Here are common signs:

Dirt and dust build up on bearings. This causes wear and can break them.

Water leaves marks or small cracks. This makes bearings weak and rusty.

Heat from outside makes bearings too hot or tired.

Electrical corrosion makes pits or grooves. This happens near electric currents.

If you see these signs, check your bearings right away.

Protection Methods

You can keep your bearings safe from the environment with smart steps. Sealed or shielded bearings block dust and water. Labyrinth or rubber seals give extra protection. Clean and check your bearings often to remove dirt and water. Using stainless steel or ceramic helps bearings last longer. Special coatings stop rust and wear.

Pick materials that resist rust for your bearings.

Use coatings to protect against rust and chemicals.

Put in good seals to keep out dirt and water.

Note: Regular care, like adding lubricant and checking condition, keeps your ball bearing working well. This helps you avoid big repairs and stops downtime.

Proper Bearing Maintenance

Routine Inspection Tips

You can keep bearings working well by checking them often. Regular checks help you find problems early and make bearings last longer. Here are some easy tips for checking bearings:

Look at the bearing and the space around it. Take a bit of the lubricant to test later. Check for dirt, heat marks, hard or black grease, or too much grease coming out.

If you need to, cut the outer race in half. Always wear safety gear when doing this.

Look at the grease. See if there are burnt spots or tiny metal pieces.

Clean all bearing parts with a degreaser or special cleaner. Always follow safety rules.

Check for small pits or a frosty look on the bearing race. These can mean the bearing is worn out or has electrical damage.

Doing these checks helps your bearings work smoothly. E-ASIA says these steps are important for good bearing care. Their testing makes sure you get strong bearings for any place.

Lubrication Schedules

Lubrication helps bearings move without problems. You need to follow a schedule to stop issues. The best time to add grease depends on the bearing, its size, the grease, and how it is used. The maker’s rules tell you when to add more grease. Things like shaking, water, and dust can change how often you need to grease bearings.

Bearing Type | RPM | Relubrication Interval | Grease Strokes | Time Frame |

6209 | 1,750 | 10,000 hours | 6 | 13 months |

6209 | 1,750 | 10,000 hours | 1 | 8 weeks |

Always use good lubricants. E-ASIA has special greases for places with lots of heat or water. These help your ball bearing last longer.

Record Keeping

Keeping records helps you plan when to fix bearings. You can make a better schedule and stop surprise problems. Good records help you know repair costs and plan your money.

You can plan when to fix things and spend less on repairs.

You stop surprise breakdowns by knowing when to fix bearings.

You can guess what parts and tools you will need, so you do not run out.

You can guess how much repairs will cost and when you will need to pay.

E-ASIA says you should keep records for every bearing. This helps you keep bearings working well and get the best use from them.

Tip: Use these care steps to keep bearings in good shape. Good products and regular checks help you stop problems and make bearings last longer.

When to Seek Expert Help

Signs for Professional Assistance

Sometimes, you need an expert to help with your bearings. There are signs that show you should not fix things alone. Watch for these warning signs:

Strange noises or shaking. Grinding or squealing means the bearing is worn out.

Bearings get too hot. This can happen if lubrication is gone or parts are not lined up.

You see damage or leaks. Flaking or leaking lubricant means the inside is getting worse.

Your machine uses more power. Bad bearings can make it work harder.

The machine acts different or slows down. Early bearing failure can cause delays.

If you notice any of these, do not wait. Getting expert help stops bigger problems. It also keeps your ball bearing working well. Use these tips to know when to call a specialist.

Choosing a Service Provider

It is important to pick the right person to fix your bearings. You want someone who knows how to solve bearing problems and gives good help. Use this table to help you choose:

Criteria | Description |

Product Quality | Make sure they sell real, high-quality bearings. This helps you avoid fake ones and stops failures. |

Technical Expertise | Pick someone who can talk to the maker. They can answer hard questions about your bearings. |

Customer Service | Look for good help after you buy. Good providers help with warranty, fixing problems, and returns. |

Responsiveness | See how fast they answer your questions. Quick help lets you fix problems before they get worse. |

Check these things before you choose. A good provider helps keep your bearings in great shape. They also give you peace of mind. Good support makes it easier to care for your bearings and do maintenance.

You can make your ball bearing last longer if you find problems early. Act quickly when you see something wrong. Doing regular checks helps you stop big breakdowns. This also keeps your bearing working well. Use these ideas to look for wear and check the lubrication. Put on seals to keep out dirt and water. Always use clean tools when you touch bearings. Follow the right steps when you put them in. Make a list to help you check and fix bearings. If you hear odd noises or feel heat, ask someone who knows more for help.

Good lubrication lowers friction and stops wear.

Regular checks stop damage and keep bearings working well.

Clean lubricants and the right way to install bearings stop dirt and misalignment.

Take care of your bearings before problems start. Use these tips to keep your bearings working strong.

FAQ

What is the best way to store ball bearings?

You should keep ball bearings in a dry, clean place. Store them in their original packaging. Avoid touching them with bare hands. This helps prevent rust and contamination.

How often should you inspect ball bearings?

Check your ball bearings every month. Look for noise, heat, or leaks. Regular checks help you find problems early and keep your machines running smoothly.

Can you reuse a ball bearing after cleaning?

You can reuse a ball bearing if it shows no damage or wear. Clean it with the right solvent. Dry it well. Always check for pits, cracks, or rough spots before reuse.

What lubricant works best for ball bearings?

Use high-quality grease or oil made for your bearing type. E-ASIA offers special lubricants for different needs. Always follow the manufacturer’s advice for the best results.

Why do ball bearings fail early?

Ball bearings fail early because of poor lubrication, contamination, misalignment, or overload. Regular maintenance and using the right products help you avoid these problems.

English

English