Technical Information

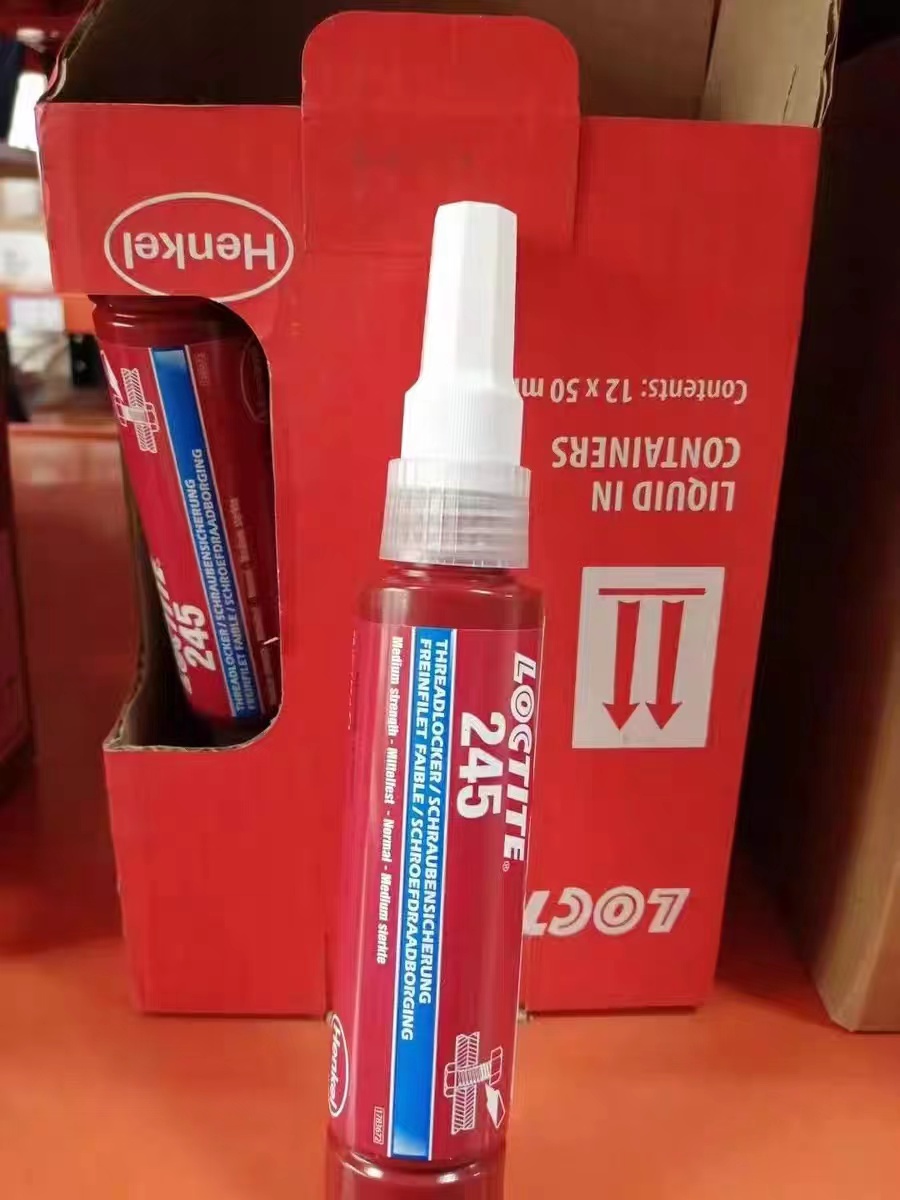

| Chemical basis / base | Methacrylate |

| Color | Blue |

| Fixture time | 12.0 - 240.0 min. |

| Key characteristics | Thixotropic |

| Recommended for use with | Metal: brass, Metal: steel, Metal: steel - stainless steel |

| Viscosity, Brookfield - RVT, @ 25.0 °C Spindle 5, speed 2.5 rpm | 5600.0 - 10000.0 mPa·s (cP) |

| Viscosity, EN 12092 - MV, @ 25.0 °C Shear Rate 129 s⁻¹ | 17500.0 - 52500.0 mPa·s (cP) |

Overview

The Loctite Electrical Insulation Adhesive is a specialized product designed to provide reliable electrical insulation and protection for various electrical components and assemblies. This adhesive is formulated to meet the stringent requirements of the electrical industry, ensuring safety and optimal performance. It creates a strong, durable bond while maintaining excellent electrical insulating properties, preventing short circuits and electrical leakage. Whether for insulating wires, connectors, circuit boards, or encapsulating sensitive electronic components, Loctite Electrical Insulation Adhesive offers a versatile solution. Available in different viscosities and curing methods, it can be tailored to specific application needs, making it an essential product for electrical and electronics manufacturing, as well as maintenance and repair.

Features

Loctite Electrical Insulation Adhesive boasts several key features. It has a high dielectric strength, which means it can withstand high electrical voltages without breaking down, providing reliable insulation. The adhesive offers excellent resistance to moisture, chemicals, and temperature fluctuations, protecting electrical components from environmental damage. It also has good adhesion to a wide range of materials, including metals, plastics, and ceramics, ensuring a secure bond. Some variants of the adhesive are designed to be flexible, allowing for movement and vibration without cracking, which is crucial for components in dynamic environments. Additionally, the adhesive can be cured quickly, either through heat, UV light, or at room temperature, depending on the formulation, enabling efficient production processes.

Benefits

Using Loctite Electrical Insulation Adhesive provides significant advantages in the electrical and electronics sectors. It enhances the safety of electrical systems by preventing electrical shorts and leakage, reducing the risk of electrical hazards. The adhesive's protective properties extend the lifespan of electrical components, minimizing the need for frequent replacements. Its ability to bond and insulate simultaneously simplifies the manufacturing process, reducing the number of assembly steps and components required. The fast - curing options increase production efficiency, allowing for quicker turnaround times. Moreover, the versatility of the adhesive in terms of application methods and material compatibility makes it suitable for a wide range of electrical projects, from small - scale repairs to large - scale industrial manufacturing.

Applications

In the electronics manufacturing industry, Loctite Electrical Insulation Adhesive is used to insulate and protect printed circuit boards (PCBs), connectors, and integrated circuits. It is applied to seal and insulate wire joints, preventing electrical interference and ensuring signal integrity. In the automotive electronics sector, the adhesive is used to encapsulate sensors, control modules, and other sensitive components, protecting them from moisture, vibrations, and temperature changes. It is also widely used in the power generation industry for insulating electrical connectors, transformers, and switchgear, ensuring the safe and efficient operation of electrical systems. Additionally, the adhesive is suitable for DIY electrical projects and home appliance repairs, providing a reliable and easy - to - use insulation solution.

FAQ

Q: What is the dielectric strength of Loctite Electrical Insulation Adhesive?

A: The dielectric strength varies depending on the specific formulation of the adhesive. Typically, it ranges from 20 to 50 kV/mm. Detailed information can be found in the product datasheet for each variant.

Q: Can this adhesive be used in high - temperature electrical applications?

A: Some formulations of the adhesive are designed for high - temperature applications and can withstand temperatures up to 200°C or more. However, it is important to check the product specifications to ensure the adhesive is suitable for the specific temperature requirements of your application.

Q: Does the adhesive require any special handling during application?

A: As with any adhesive, it is important to follow the manufacturer's instructions for proper handling. Ensure that the surfaces to be bonded are clean and dry. When using heat - cure or UV - cure variants, use the appropriate equipment and follow the recommended curing procedures. In some cases, wearing gloves and working in a well - ventilated area may be advisable.

English

English