Introduction

Loctite Adhesive has become a cornerstone in various industries due to its superior bonding capabilities and reliability. Understanding the drying time of this adhesive is crucial for professionals who rely on its performance for critical applications. This article delves into the factors affecting the drying time of Loctite Adhesive, providing a comprehensive analysis backed by scientific principles and industry data. By exploring the intricacies of this adhesive, we aim to equip readers with the knowledge to optimize its use in their respective fields.

For a deeper understanding of the applications of Loctite Adhesive, you may explore our extensive range of products that utilize this adhesive in various configurations.

Factors Influencing Drying Time

The drying time of Loctite Adhesive is not a fixed parameter; it varies depending on several factors. These include the ambient temperature, humidity levels, the materials being bonded, and the specific type of Loctite Adhesive used. Understanding these factors is essential for predicting and controlling the curing process in practical applications.

Ambient Temperature

Temperature plays a significant role in the curing process of Loctite Adhesive. Higher temperatures generally accelerate the chemical reactions involved in the curing process, leading to a shorter drying time. Conversely, lower temperatures can slow down these reactions, resulting in longer drying times. It is recommended to use the adhesive in environments where the temperature is within the optimal range specified by the manufacturer to ensure reliable bonding.

Humidity Levels

Humidity affects the drying time by influencing the rate at which solvents within the adhesive evaporate. High humidity can slow down evaporation, prolonging the drying time, while low humidity can accelerate it. For applications requiring precise drying times, controlling the humidity levels in the working environment is advisable.

Material Compatibility

Different materials interact with Loctite Adhesive in various ways. Porous materials may absorb some of the adhesive, affecting the amount available for bonding and altering the drying time. Non-porous materials provide a consistent surface for the adhesive to cure. It is essential to consider the materials involved to predict the adhesive's performance accurately.

Types of Loctite Adhesive and Their Drying Times

Loctite offers a range of adhesives designed for specific applications, each with its unique drying time. Some common types include threadlockers, retaining compounds, and instant adhesives. Understanding the characteristics of each can help in selecting the appropriate adhesive for a particular application.

Threadlockers

Loctite threadlockers are anaerobic adhesives designed to lock and seal threaded fasteners, preventing loosening due to vibration. The typical drying time for these adhesives ranges from 10 to 20 minutes for initial set, with full cure achieved in 24 hours. Factors such as primer use and substrate material can influence these times.

For more technical specifications on threadlockers, please visit our support page for detailed information.

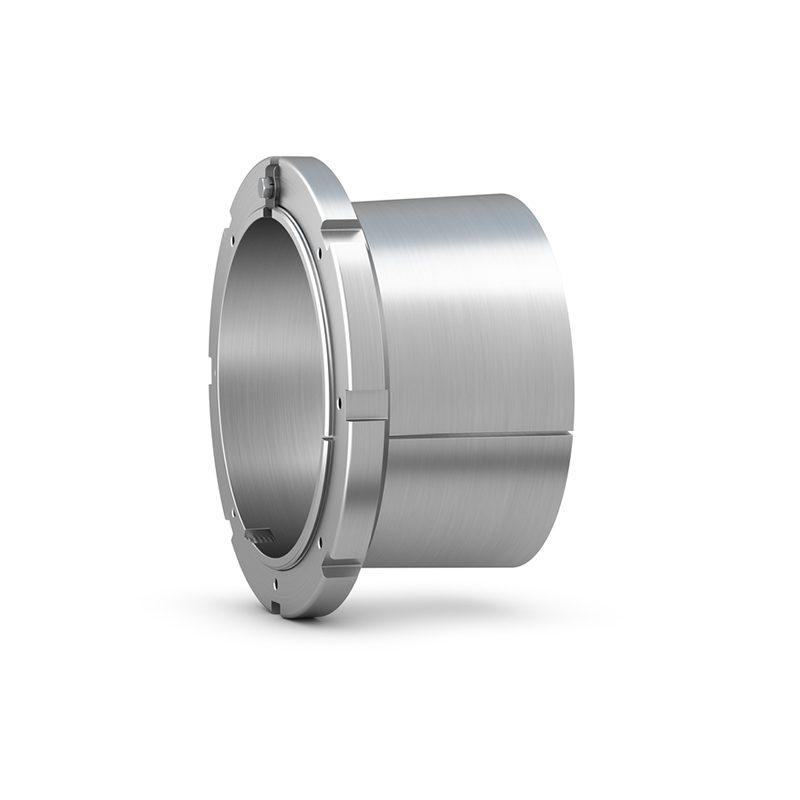

Retaining Compounds

Retaining compounds are used to bond non-threaded, cylindrical metal assemblies. They typically have a slightly longer drying time compared to threadlockers, with fixture times ranging from 20 minutes to several hours, depending on the formulation. Full cure is generally achieved within 24 hours.

Instant Adhesives

Also known as cyanoacrylates, Loctite's instant adhesives are designed for rapid bonding. They can achieve handling strength in as little as a few seconds, with full cure in 24 hours. These adhesives are ideal for applications requiring quick assembly with minimal clamping time.

Accelerating the Drying Process

In scenarios where time is of the essence, there are methods to accelerate the drying time of Loctite Adhesive. Applying heat is a common approach, as increased temperatures can speed up the curing process. However, it is crucial to ensure that the heat applied does not adversely affect the materials being bonded or the integrity of the adhesive.

Using primers or activators is another method to reduce drying time. These substances prepare the bonding surfaces, enhancing the adhesive's curing properties. Loctite offers specific primers compatible with their adhesives, and selecting the right one can significantly improve performance.

Practical Applications and Case Studies

Understanding the drying time is critical in industries where downtime equates to significant financial loss. For instance, in the assembly of automotive components, knowing the exact curing time allows for efficient production scheduling. A case study showed that by optimizing the use of Loctite Adhesive, a manufacturing plant reduced assembly time by 15%, leading to increased productivity.

In another example, the aerospace industry relies on precise bonding processes. Engineers must account for environmental variables affecting the adhesive's drying time to ensure the safety and reliability of aircraft components. Detailed protocols are established to maintain consistent curing conditions, demonstrating the importance of understanding Loctite Adhesive's properties.

Expert Recommendations

Professionals recommend conducting preliminary tests to determine the drying time under specific conditions. This approach accounts for variables unique to each application. Additionally, adhering to the manufacturer's guidelines ensures optimal performance. Experts also highlight the importance of surface preparation, as contaminants can significantly hinder the curing process.

For advice on the best practices when using Loctite Adhesive, our FAQ section provides answers to common questions and expert insights.

Understanding Safety Precautions

Safety is paramount when working with adhesives. Loctite Adhesive requires handling with care to prevent health risks. Proper ventilation is essential to avoid inhaling fumes, and protective equipment should be worn to prevent skin contact. Understanding the drying time also plays a role in safety, as premature handling can lead to joint failure, posing potential hazards.

Conclusion

The drying time of Loctite Adhesive is a critical factor that impacts its performance in various applications. By understanding the influencing factors and following expert recommendations, users can optimize the adhesive's effectiveness. Whether in manufacturing, construction, or repairs, accounting for the adhesive's properties ensures strong, reliable bonds that meet the demands of modern industries.

For further information on our range of adhesives and their applications, please visit our about us page or contact our support team.

English

English