Introduction

In the world of mechanical engineering, bearings play a pivotal role in reducing friction between moving parts, thereby enhancing efficiency and longevity of machinery. Among the various types of bearings, roller bearings and spherical bearings are commonly used, each serving specific applications based on their unique designs and characteristics. Understanding the differences between these two types of bearings is crucial for engineers and technicians when selecting the appropriate component for machinery. This article delves into the fundamental distinctions between roller bearings and spherical bearings, providing insights into their designs, operational principles, applications, and advantages. By exploring these aspects, readers will gain a comprehensive understanding of how to optimize machinery performance through informed bearing selection. Explore more about Roller Bearing and its significance in modern engineering.

Design and Structural Differences

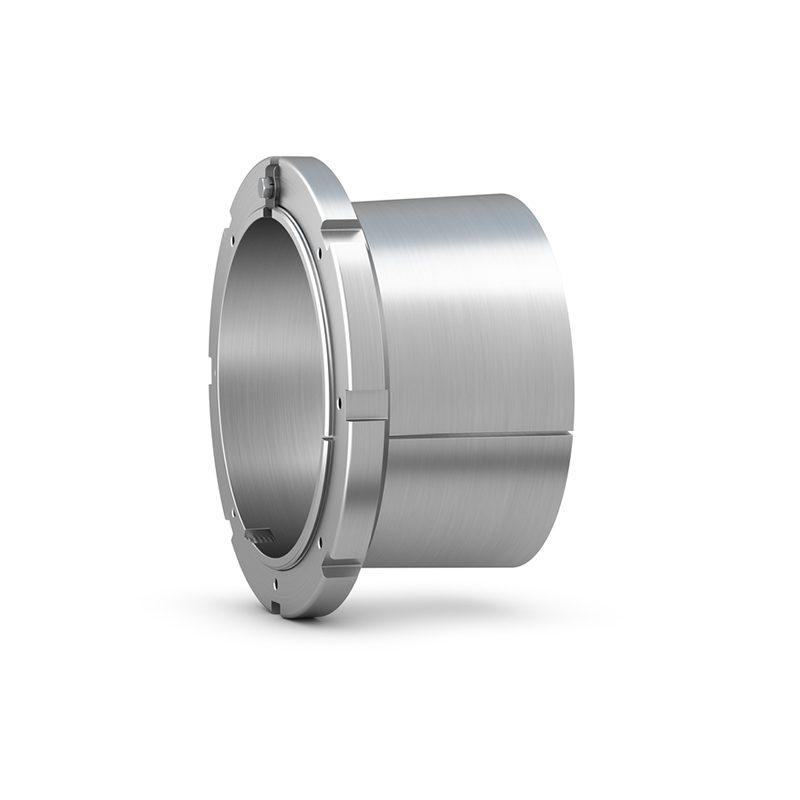

The primary difference between roller bearings and spherical bearings lies in their design and the way they handle load and misalignment. Roller bearings are characterized by cylindrical rolling elements that facilitate motion and support radial loads. They consist of inner and outer rings with rollers sandwiched between them, allowing for smooth rotational motion under heavy radial loads. On the other hand, spherical bearings feature spherical rolling elements or surface contacts that enable the bearing to accommodate angular misalignments. This self-aligning capability is due to the spherical shape of the inner ring raceway, which matches the curvature of the rolling elements.

Roller Bearings

Roller bearings are designed to carry heavy loads with minimal friction. The rollers, which are cylindrical in shape, provide a larger contact area with the raceways compared to ball bearings. This larger contact area allows roller bearings to support higher radial loads. Moreover, roller bearings come in various types, such as cylindrical, tapered, needle, and thrust roller bearings, each suited for specific applications.

For instance, cylindrical roller bearings are efficient for high-speed applications and can accommodate axial displacement. Tapered roller bearings are suitable for combined radial and axial loads, commonly used in automotive wheel hubs. Needle roller bearings, with their slender rollers, are ideal for applications where space is limited but high load capacity is required. Explore detailed applications of Roller Bearing in various industries.

Spherical Bearings

Spherical bearings, including spherical roller bearings and spherical plain bearings, are designed to accommodate misalignment between the shaft and housing. Spherical roller bearings have barrel-shaped rollers positioned between an inner ring with two raceways and an outer ring with a single spherical raceway. This configuration allows the bearing to tolerate angular misalignments caused by shaft deflection or mounting errors.

Spherical plain bearings, also known as bushings, feature a sliding contact surface with a spherical shape, suitable for oscillating movements and where rotational alignment is necessary. They are commonly used in heavy-duty off-road vehicles, agricultural machinery, and industrial equipment where shock loads and misalignments are prevalent.

Load Capacity and Performance

When it comes to load capacity, both roller and spherical bearings are capable of handling significant loads, but their performance varies based on the type of load and operational conditions.

Radial and Axial Loads

Roller bearings are primarily designed to support radial loads due to the line contact between the rollers and raceways. However, certain types like tapered roller bearings can handle combined radial and axial loads. The ability to support axial loads depends on the bearing's design and the angle of the contact surfaces.

Spherical bearings, particularly spherical roller bearings, are adept at handling heavy radial loads and moderate axial loads in both directions. Their design allows for the distribution of stress over a larger area, making them suitable for applications involving high loads and misalignments.

Misalignment Accommodation

A significant advantage of spherical bearings is their ability to accommodate misalignment. Spherical roller bearings can adjust for shaft deflections and misalignments up to several degrees without compromising performance. This self-aligning feature makes them ideal for applications where precise alignment is challenging to maintain.

Roller bearings generally require precise alignment, as misalignment can lead to increased stress on the rollers and raceways, resulting in premature failure. In applications where alignment cannot be guaranteed, spherical bearings are often the preferred choice.

Operational Speed and Efficiency

Operational speed is a critical factor when selecting a bearing, as it affects both performance and longevity. Roller bearings are suitable for high-speed applications due to their rolling elements minimizing friction. The design of the cages and lubrication methods further enhance their speed capabilities.

Spherical bearings, while capable of handling heavy loads and misalignments, typically operate at lower speeds compared to roller bearings. The increased contact area and the nature of the misalignment accommodation introduce higher friction levels, which can limit their speed. Therefore, in applications where high-speed operation is essential, roller bearings are often preferred.

Applications in Industry

Both roller bearings and spherical bearings find applications across various industries, each selected based on specific operational requirements.

Roller Bearing Applications

Roller bearings are extensively used in industries such as automotive, aerospace, and industrial machinery. In automotive applications, they are used in transmissions, differentials, and wheel hubs due to their ability to handle high radial loads and support rotation at high speeds. In industrial machinery, roller bearings facilitate the smooth operation of conveyor belts, gearboxes, and electric motors.

The aerospace industry relies on roller bearings for critical components where reliability and performance are paramount. Their precision and efficiency contribute to the safe and effective operation of aircraft systems.

Spherical Bearing Applications

Spherical bearings are favored in heavy machinery, construction equipment, and applications where shaft deflection or misalignment is common. This includes equipment like crushers, vibrating screens, and heavy-duty gearboxes in mining and construction industries. Their ability to handle shock loads and compensate for misalignment extends the service life of machinery under harsh operating conditions.

In agricultural equipment, spherical bearings ensure reliable operation despite uneven terrain and heavy loads. They are also used in continuous casting machines in the steel industry, where they must endure high temperatures and loads while accommodating shaft deflections.

Maintenance and Lifespan Considerations

The maintenance requirements and expected lifespan of bearings are critical factors influencing their selection.

Roller Bearings

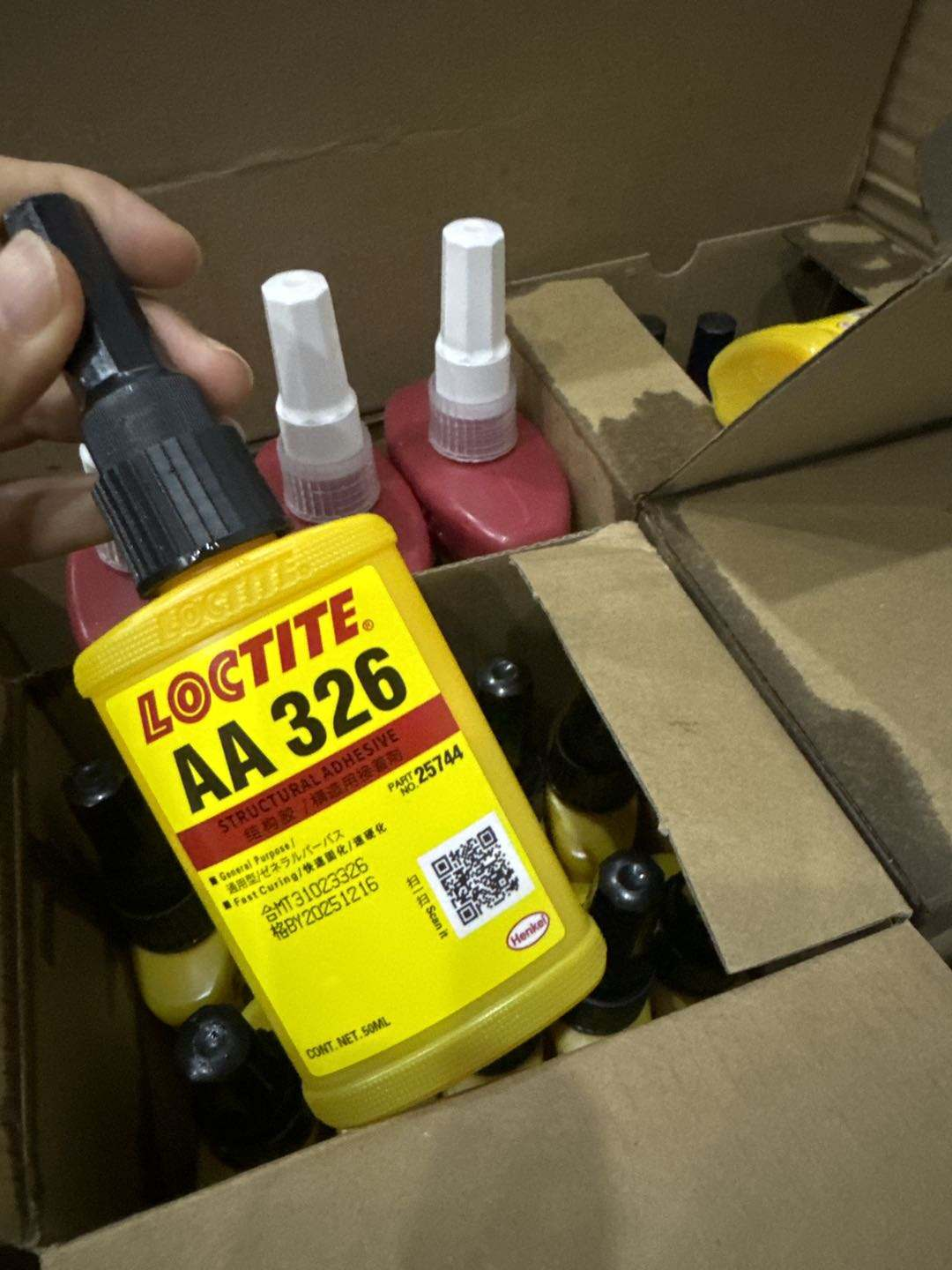

Roller bearings generally have a long service life when properly maintained. Regular lubrication minimizes friction and wear, reducing the risk of failure. However, due to their sensitivity to misalignment, inadequate installation or mounting can lead to premature wear and failure. Implementing proper alignment during installation and routine inspections is essential to extend their operational life.

Spherical Bearings

Spherical bearings are robust and can withstand harsh conditions with less frequent maintenance. Their design inherently accommodates alignment issues, reducing stress on the bearing components. Additionally, spherical bearings can tolerate contamination better than roller bearings, making them suitable for environments where cleanliness is challenging to maintain.

Cost Implications

Cost is always a significant consideration in component selection. Roller bearings are typically less expensive than spherical bearings due to their simpler design and lower material costs. However, the total cost of ownership must consider maintenance, potential downtime due to failure, and the impact of misalignment issues.

Spherical bearings, while more expensive upfront, may offer cost savings over time by reducing maintenance requirements and extending machinery life. In applications where misalignment is unavoidable, the additional cost of spherical bearings can be justified by improved performance and reliability.

Case Study: Industrial Machinery Comparison

Consider a scenario in an industrial setting where heavy machinery operates under high loads with potential shaft misalignments. A company initially uses roller bearings due to their lower cost and high load capacity. However, frequent bearing failures occur, leading to costly downtime and repairs. Upon analysis, it is determined that misalignment is causing excessive stress on the roller bearings.

By switching to spherical bearings, the machinery can accommodate the misalignment, significantly reducing failures. Although the spherical bearings have a higher initial cost, the company experiences improved machinery reliability and reduced maintenance costs, resulting in overall savings and increased productivity.

Expert Opinions

Industry experts emphasize the importance of selecting the right type of bearing for specific applications. John Smith, a senior mechanical engineer, states, "Understanding the operational environment and load conditions is crucial. While roller bearings are excellent for high-speed and well-aligned applications, spherical bearings provide a solution when dealing with misalignment and heavy loads."

Dr. Emily Johnson, a professor of mechanical engineering, adds, "The choice between roller and spherical bearings can significantly impact the efficiency and lifespan of machinery. Engineers must consider not just the immediate costs but the long-term implications of their selection."

Conclusion

In conclusion, the difference between roller bearings and spherical bearings is rooted in their design, load capacity, ability to accommodate misalignment, operational speed, and maintenance requirements. Roller bearings are ideal for applications requiring high-speed operation and precise alignment, offering efficient performance under heavy radial loads. Spherical bearings, conversely, are suited for environments where misalignment and heavy loads are prevalent, providing durability and reducing maintenance needs.

Selecting the appropriate bearing is essential for optimizing machinery performance, reducing downtime, and lowering overall costs. Engineers should conduct a thorough analysis of application requirements, considering factors such as load types, alignment conditions, operational speeds, and environmental conditions. By doing so, they can make informed decisions that enhance efficiency and extend the lifespan of equipment.

For more detailed information on selecting the right bearing for your application, visit our comprehensive guide on Roller Bearing solutions and discover how to maximize your machinery's performance.

English

English