Introduction

Pillow block bearings are critical for supporting rotating shafts in many industries. These components reduce friction, ensuring smoother machinery operations. With various designs available, they serve diverse applications across manufacturing, agriculture, and automotive sectors.

In this article, we will explore the different types of pillow block bearings. You’ll learn how to select the right type to optimize performance and extend machinery life.

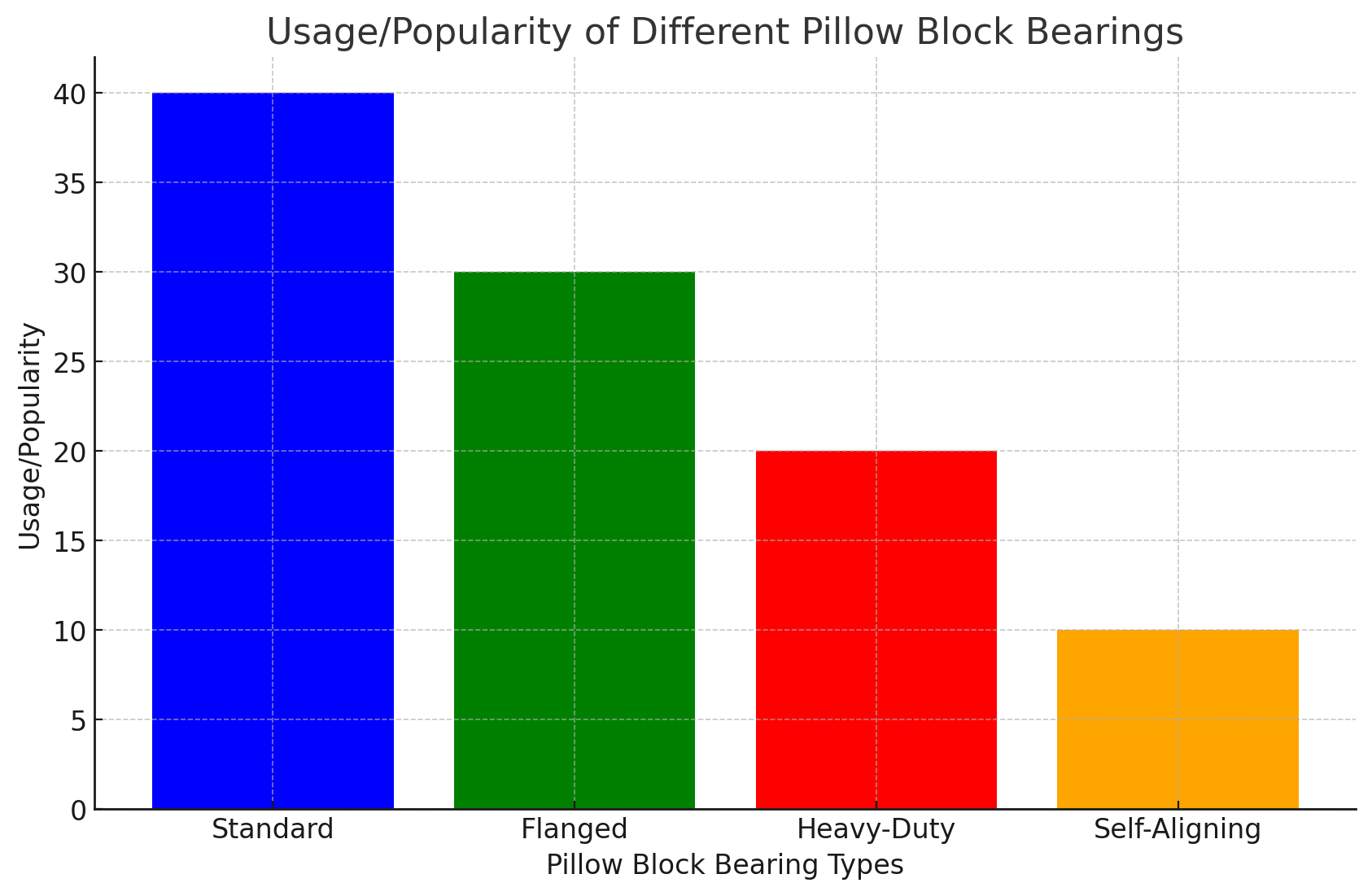

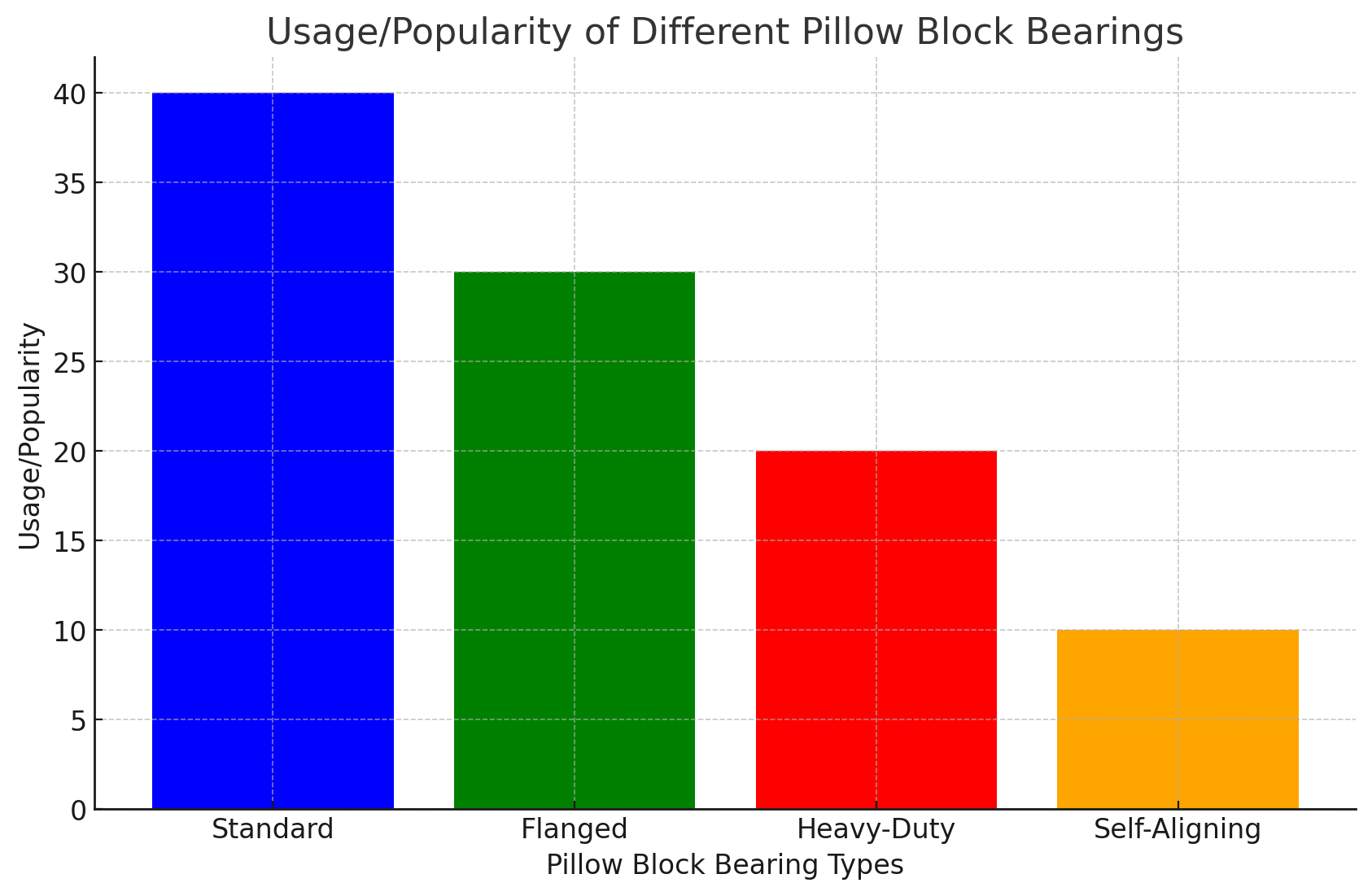

Types of Pillow Block Bearings

Standard Pillow Block Bearings

Standard pillow block bearings are the most common type. They consist of a bearing insert housed within a mounting block, providing a straightforward, cost-effective solution for many applications.

These bearings are ideal for applications requiring moderate load capacity and speed. They are commonly used in conveyors, HVAC systems, and agricultural equipment.

Flanged Pillow Block Bearings

Flanged pillow block bearings are similar to standard pillow blocks, but with an added flange. This design allows for easier mounting and secure attachment to surfaces where the bearing needs to be positioned perpendicular to the shaft.

Flanged pillow blocks are often used in applications where additional support is required, such as in high-load machinery or when space constraints require a more compact design.

Heavy-Duty Pillow Block Bearings

Heavy-duty pillow block bearings are designed to handle larger loads and more rigorous conditions. These bearings feature reinforced housings and bearings capable of withstanding high-impact environments.

Industries like mining, construction, and material handling often rely on heavy-duty pillow blocks for their strength and durability. These bearings excel in applications with heavy, continuous loads or where machinery is subjected to shock and vibration.

Self-Aligning Pillow Block Bearings

Self-aligning pillow block bearings are unique in their ability to compensate for misalignment. They feature a spherical outer ring that allows for alignment adjustments without causing excessive wear.

These bearings are especially useful in situations where shafts may not be perfectly aligned, as they can help maintain smooth operation even under misalignment, reducing the risk of premature bearing failure.

Bearing Type | Description | Common Use |

Standard Pillow Block | Basic design, cost-effective. Supports moderate loads. | Conveyor systems, agricultural equipment. |

Flanged Pillow Block | Features a flange for additional mounting options. | Compact spaces, machinery with perpendicular shafts. |

Heavy-Duty Pillow Block | Reinforced housing for high-load applications. | Mining, construction, heavy-duty machinery. |

Self-Aligning Pillow Block | Can compensate for shaft misalignment. | Applications with misaligned shafts. |

Types of Bearing Inserts Used in Pillow Block Bearings

Ball Bearings

Ball pillow block bearings are one of the most commonly used inserts in pillow block housings. They are versatile and capable of handling both radial and axial loads. Ball bearings are best suited for low to moderate load applications that require high speed and minimal friction.

Ball bearings are ideal for light-duty applications, such as in conveyor belts and small machinery, where high speeds are required but the loads are relatively low.

Roller Bearings

Roller bearings offer higher load capacities than ball bearings, making them ideal for applications with higher radial loads. These bearings use cylindrical rollers instead of balls to reduce rolling resistance and increase load support.

In heavy-load applications, such as in industrial machinery or construction equipment, roller bearings provide the necessary strength and stability. They are particularly effective in environments where heavy and constant loads are present.

Spherical Roller Bearings

Spherical roller bearings are designed to handle both radial and axial loads, making them suitable for high-impact applications. Their self-aligning nature allows them to handle misalignment without damaging the bearing, which makes them valuable in harsh environments.

These bearings are commonly used in heavy-duty industrial equipment like crushers, mining machinery, and large motors, where both high load capacities and alignment flexibility are essential.

Cylindrical Roller Bearings

Cylindrical roller bearings are designed for applications requiring high radial load capacities and higher speeds. They perform well in machinery where precision is key and can handle large radial loads with low friction.

These bearings are used in high-speed applications, such as textile machinery, and in automotive equipment where high-performance and precise operation are critical.

Key Considerations When Choosing Pillow Block Bearings

Load Capacity

When selecting a pillow block bearing, understanding the load requirements is crucial. Bearings must be able to support the weight and stress imposed by the machinery they are installed in. Overloading can cause premature wear or failure.

The load capacity of pillow block bearings varies by type, so it’s essential to match the bearing with the load requirements of the application.

Speed and Lubrication Needs

The speed at which the bearing operates impacts its performance and lifespan. Bearings designed for high-speed applications require special materials and lubricants to minimize heat and friction.

Proper lubrication is vital for extending the life of the bearing and reducing the risk of failure. Lubricants help to maintain smooth operation by reducing friction between moving parts.

Environmental Factors

Environmental conditions such as moisture, temperature, and exposure to chemicals or dirt can impact bearing performance. Choosing the correct material and sealing options helps protect the bearing from contaminants and harsh conditions, ensuring it operates efficiently for longer.

For instance, stainless steel bearings offer excellent corrosion resistance, making them ideal for food processing or marine environments.

Factor | Consideration | Impact on Bearing Selection |

Load Capacity | Determines the amount of weight the bearing must support. | Choosing a bearing with sufficient load capacity prevents premature failure. |

Speed | How fast the bearing will rotate. | High-speed applications require specialized bearings with reduced friction. |

Environmental Conditions | Exposure to moisture, dust, or chemicals. | Choosing the right material and sealing improves bearing durability in harsh environments. |

Pillow Block Bearing Materials

Cast Iron

Cast iron is one of the most common materials used for pillow block bearing housings. It provides durability, strength, and vibration damping, making it ideal for many industrial applications.

Applications include heavy-duty machinery and agricultural equipment, where the bearing is subjected to constant stress and vibration.

Stainless Steel

Stainless steel pillow block bearings are ideal for use in harsh environments. These bearings are highly resistant to corrosion, making them perfect for applications in the food and beverage industry, pharmaceuticals, and marine environments.

Their durability ensures they can withstand exposure to moisture, chemicals, and high temperatures.

Thermoplastic and Other Materials

Thermoplastic materials, such as nylon and acetal, are lightweight, resistant to chemicals, and often self-lubricating. These properties make them perfect for light-duty applications where corrosion resistance and low maintenance are important.

They are commonly used in packaging machinery and electronics, where durability and low friction are essential.

Material | Benefits | Common Use |

Cast Iron | Strong, cost-effective, provides good vibration damping. | Industrial machinery, conveyors, agriculture. |

Stainless Steel | Corrosion-resistant, ideal for harsh environments. | Food processing, marine, and pharmaceutical industries. |

Thermoplastic | Lightweight, corrosion-resistant, often self-lubricating. | Light-duty applications, electronics, and packaging machinery. |

Common Applications of Pillow Block Bearings

Manufacturing and Conveyor Systems

Pillow block bearings are crucial in manufacturing environments, particularly in conveyor systems. They support rotating shafts and help ensure smooth operation in assembly lines, reducing the risk of downtime.

These bearings are also used in motors, pumps, and other machinery that require constant rotational support.

Agricultural Equipment

Pillow block bearings are found in many agricultural machines, including tractors, harvesters, and balers. Their ability to handle heavy loads and operate in harsh outdoor conditions makes them indispensable for farming equipment.

They are used to support rotating shafts in equipment that must endure rough handling and exposure to dust and debris.

Automotive and Heavy Machinery

Pillow block bearings are critical in automotive and construction machinery, supporting shafts in engines, transmissions, and suspension systems. Their ability to handle high loads and withstand high temperatures ensures reliability and performance in demanding applications.

Maintenance and Troubleshooting of Pillow Block Bearings

Regular Lubrication and Inspection

To maintain the performance and lifespan of pillow block bearings, regular lubrication and inspections are essential. Lubrication reduces friction and wear, while inspections help identify early signs of damage or misalignment.

Regular maintenance ensures that bearings continue to function smoothly, minimizing unexpected downtime and extending the service life of machinery.

Identifying Common Issues

Some common issues with pillow block bearings include wear, misalignment, and insufficient lubrication. Regularly checking for signs of excessive noise, vibration, or overheating can help identify these problems early.

Prompt attention to these issues can prevent more significant failures and ensure continued smooth operation.

Conclusion

Pillow block bearings are essential for supporting rotating shafts across industries. Understanding their types and considering factors like load capacity, speed, and environmental conditions helps businesses choose the right bearing. Regular maintenance and lubrication ensure long-term performance.

EASIA Bearings offers a wide range of high-quality pillow block bearings, providing exceptional value through reliability and durability, making them an excellent choice for various industrial needs.

FAQ

Q: What is a pillow block bearing?

A: A pillow block bearing is a mounted bearing designed to support a rotating shaft. It provides stability and reduces friction, ensuring smooth operation in various applications.

Q: What are the different types of pillow block bearings?

A: The main types of pillow block bearings include standard, flanged, heavy-duty, and self-aligning. Each type is suited to specific load capacities and environmental conditions.

Q: How do I choose the right pillow block bearing?

A: Consider factors like load capacity, shaft size, speed, and environmental conditions. The correct choice ensures optimal performance and longer bearing life.

Q: What is the advantage of self-aligning pillow block bearings?

A: Self-aligning pillow block bearings can compensate for misalignment, reducing wear and tear in applications with shaft misalignment, ensuring smoother operation.

Q: Where are pillow block bearings commonly used?

A: Pillow block bearings are used in manufacturing, agriculture, automotive, and heavy machinery. They support shafts in conveyors, motors, and construction equipment.

Q: How can I extend the lifespan of my pillow block bearing?

A: Regular lubrication and timely inspections are key to extending the life of pillow block bearings. Addressing wear and misalignment early prevents costly repairs.

Q: What materials are pillow block bearings made from?

A: Pillow block bearings are commonly made from cast iron, stainless steel, and thermoplastic materials. The material choice depends on environmental conditions and load requirements.

English

English