Introduction

In industrial machinery, choosing the right bearing type is crucial. Plummer block and pillow block bearings both support rotating shafts but have key differences. This article explores these differences, helping you understand their construction, applications, and which is best for your needs. You will learn the features, benefits, and ideal uses for both types of bearings.

What is a Pillow Block Bearing?

Basic Definition and Construction

A pillow block bearing is a mounted bearing unit that supports a rotating shaft. Typically made from cast iron or stainless steel, the pillow block consists of a bearing insert that is secured within a housing, also known as a pillow block. The housing provides support to the bearing, allowing it to rotate smoothly while also minimizing friction. Pillow block bearings are commonly used in applications that involve lower loads and less demanding conditions.

Common Applications of Pillow Block Bearings

Pillow block bearings are ideal for applications such as conveyor systems, agricultural machinery, and light-duty manufacturing equipment. Their ability to support long shafts with ease makes them indispensable in industries that require reliable shaft support for continuous rotation. They are often employed in situations where there is minimal shock load and the shaft rotates at a consistent speed.

Types of Pillow Block Bearings

Pillow block bearings come in various types, with the most common being ball bearings, roller bearings, and sleeve bearings. Ball bearings are widely used for their low friction and efficiency in high-speed operations. Roller bearings, on the other hand, are designed to handle heavier loads and are used in applications where there is more force exerted on the shaft. Sleeve bearings are used in low-speed, low-cost applications where noise and vibration are not critical concerns.

What is a Plummer Block Bearing?

Basic Definition and Construction

Plummer block bearings are similar to pillow block bearings in function but differ in size, strength, and design. They are often made from stronger materials such as cast iron and are designed to accommodate higher loads. The plummer block has a robust housing that supports large, heavy-duty bearings, and it can handle both radial and axial loads. Typically, plummer block bearings are used in industries that require high-load capabilities, such as heavy machinery and industrial equipment.

Common Applications of Plummer Block Bearings

Plummer block bearings are typically used in industries such as mining, construction, and heavy manufacturing. They provide support for large machinery and equipment, including crushers, conveyors, and motors. Their design allows them to withstand harsh environmental conditions and high power loads, making them essential for industrial operations where durability and strength are critical.

Bearing Type | Common Applications |

Pillow Block Bearing | Conveyor systems, agricultural equipment, light manufacturing |

Plummer Block Bearing | Mining, construction, industrial machinery, heavy-duty equipment |

Key Features of Plummer Block Bearings

Plummer block bearings are distinguished by their heavy-duty design and ability to handle large loads. They are typically equipped with robust seals and are available in various configurations, including split housings for easy maintenance. These bearings are capable of operating in more extreme conditions, including high temperatures and heavy vibration, due to their durable construction.

Key Differences Between Plummer Block and Pillow Block Bearings

Structural Differences

One of the primary differences between plummer block and pillow block bearings is their size and construction. Pillow block bearings are generally smaller, lighter, and simpler, making them ideal for low-to-medium load applications. In contrast, plummer block bearings have larger, more reinforced housings designed to support heavier loads and endure more demanding conditions. While both types of bearings have housings to support the bearing inserts, plummer blocks are typically made of stronger materials and have larger mounting capabilities.

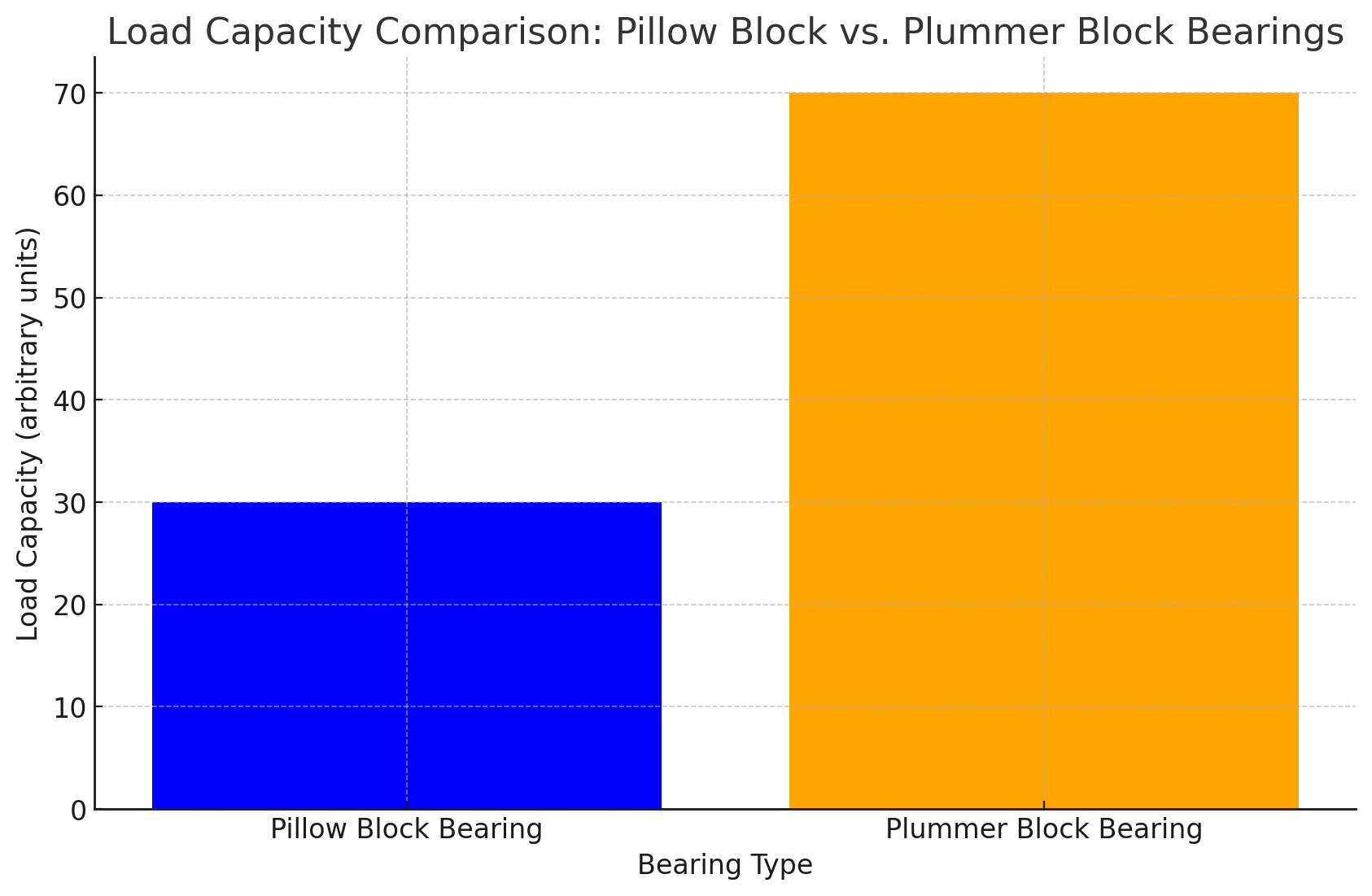

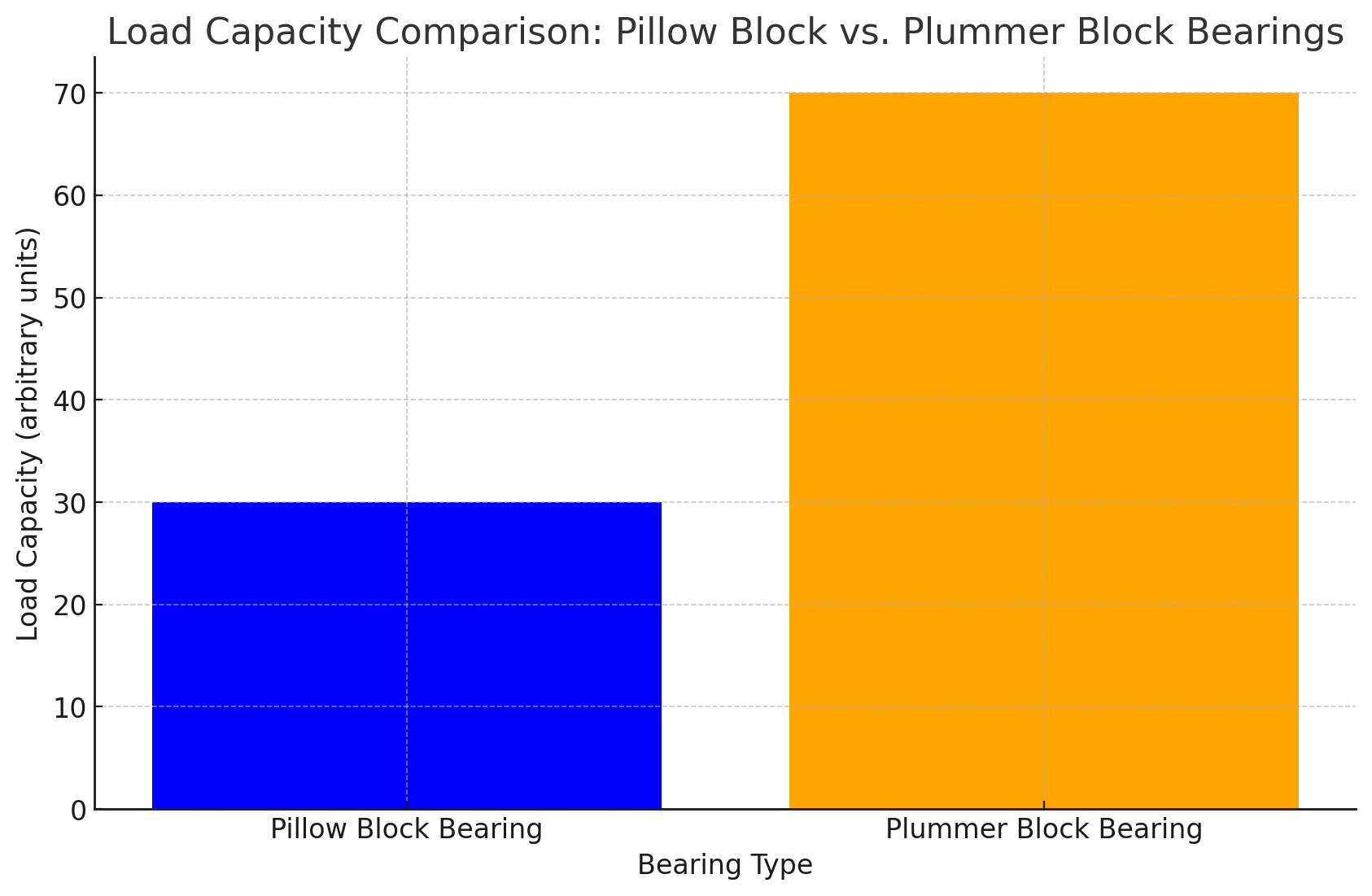

Load Capacity and Application Differences

Pillow block bearings are best suited for lighter, less demanding applications. These include machinery that operates at moderate speeds with relatively low loads. In contrast, plummer block bearings are designed to support much heavier loads and are used in industries like mining and construction where equipment handles large forces. Plummer blocks are ideal for high-torque applications and environments that require robust machinery.

Installation and Maintenance

Pillow block bearings are generally easier to install and maintain than plummer block bearings. Their design allows for quick installation and replacement, making them a more cost-effective option in systems with frequent maintenance needs. Plummer block bearings, due to their larger size and more complex installation, require more effort and precision during installation. However, their robust design ensures longer service life even in harsh conditions.

Cost and Durability Comparison

Pillow block bearings are more affordable and are suitable for applications that do not require the high load-bearing capacity of plummer block bearings. They provide reliable performance in systems that experience less strain. On the other hand, plummer block bearings, though more expensive, offer superior durability and are built for demanding industrial environments. Their ability to handle heavy loads and harsh conditions justifies the higher investment in industries where reliability and longevity are paramount.

Feature | Pillow Block Bearing | Plummer Block Bearing |

Application | Light to moderate load applications | Heavy-duty applications |

Design and Size | Compact, simple design | Larger, more robust design |

Load Capacity | Suitable for lower loads | Designed to handle high loads |

Installation | Easier and quicker installation | More complex installation |

Cost | More cost-effective | Higher cost due to durability and size |

Durability | Suitable for moderate environments | Built for harsh environments and heavy usage |

Advantages and Disadvantages of Each Bearing Type

Advantages of Pillow Block Bearings

Pillow block bearings are easy to install, maintain, and replace. They are versatile, affordable, and suitable for various light to moderate load applications. These bearings are commonly used in manufacturing, conveyor systems, and agricultural machinery, where low-cost, reliable shaft support is required. Additionally, pillow block bearings can accommodate minor shaft misalignment, making them ideal for flexible and adaptable installations.

Disadvantages of Pillow Block Bearings

The main limitation of pillow block bearings is their inability to support heavy loads or withstand extreme conditions. While they perform well under moderate loads, they are not suitable for high-torque or high-impact applications. Additionally, their design may limit their ability to operate efficiently in very high-speed environments or when subjected to excessive stress.

Advantages of Plummer Block Bearings

Plummer block bearings are robust, durable, and ideal for high-load applications. Their heavy-duty design allows them to operate in harsh environments, including mining, construction, and heavy industrial machinery. They are built to withstand high levels of shock, vibration, and extreme temperatures, making them indispensable for critical machinery that requires consistent performance under difficult conditions.

Disadvantages of Plummer Block Bearings

The primary downside of plummer block bearings is their higher cost and more complex installation. These bearings are typically larger and require precise alignment during installation, which can increase labor and downtime. Additionally, plummer block bearings may not be necessary for applications that do not involve high loads or extreme environments, making them less cost-effective in such cases.

Bearing Type | Advantages | Disadvantages |

Pillow Block Bearing | Easy installation, cost-effective, versatile | Limited load capacity, not suitable for high-duty |

Plummer Block Bearing | High load capacity, durable, suitable for harsh environments | Higher cost, more complex installation |

Selecting the Right Bearing for Your Application

Factors to Consider

When selecting between plummer block and pillow block bearings, several factors must be considered, including load capacity, speed, environmental conditions, and maintenance requirements. Pillow block bearings are ideal for lighter applications, while plummer block bearings are necessary for heavy-duty machinery. Consider the operating environment and the type of machinery being used to make the best choice.

Choosing Between Plummer and Pillow Block Bearings

For light-duty applications that require easy installation and low-cost maintenance, pillow block bearings are the best option. However, if your machinery is subjected to heavy loads, extreme temperatures, or harsh environments, plummer block bearings will provide the strength and durability needed to ensure long-term performance. Make sure to evaluate the specific demands of your application before making a decision.

Conclusion

In conclusion, plummer block and pillow block bearings both support rotating shafts but serve different needs. Pillow block bearings are cost-effective and easy to install, making them ideal for lighter applications. In contrast, plummer block bearings are more robust, handling heavy loads and tough environments. Understanding these differences helps you choose the right bearing, ensuring optimal machinery performance. EASIA bearings provides high-quality options, offering durability and reliability for diverse industrial applications.

FAQ

Q: What is the difference between a plummer block and a pillow block bearing?

A: A plummer block bearing is designed for heavy-duty applications, handling high loads and harsh environments, while a pillow block bearing is ideal for lighter loads with easier installation.

Q: Where are pillow block bearings commonly used?

A: Pillow block bearings are often used in conveyor systems, agricultural machinery, and light industrial applications, offering cost-effective support for rotating shafts.

Q: Can pillow block bearings handle heavy-duty applications?

A: Pillow block bearings are not designed for heavy-duty tasks. For high-load applications, plummer block bearings are more suitable due to their robust design.

Q: What are the advantages of pillow block bearings?

A: Pillow block bearings are cost-effective, easy to install, and suitable for moderate load applications, making them ideal for simpler mechanical systems.

Q: Which bearing is better for high-load environments?

A: Plummer block bearings are better suited for high-load and heavy-duty applications, thanks to their durable construction and robust support capabilities.

English

English