Introduction

Bearings are critical in machinery, reducing friction and enabling smooth movement. But sometimes, standard bearings aren't enough. This is where special bearings come into play.

Special bearings are tailored to handle unique challenges, from high-speed rotations to extreme environmental conditions. They are customized for industries such as aerospace, automotive, and agriculture.

In this article, we’ll explore the different types of special bearings, their advantages, and how they enhance machinery performance, longevity, and reliability.

Types of Special Bearings

Ball Bearings

Ball bearings are one of the most commonly used types of bearings across industries. They reduce friction by utilizing balls as rolling elements, which are held between two races. However, certain applications require more specialized versions of ball bearings to handle specific loads or environmental conditions.

Deep Groove Ball Bearings

These bearings are versatile and capable of handling both radial and axial loads. They are commonly found in motors, automotive applications, and conveyor systems. Special versions of these bearings are often used in high-speed machinery, where low friction and durability are crucial.

Angular Contact Ball Bearings

These bearings are designed to handle both radial and axial loads simultaneously. Their angular design allows them to support higher loads compared to standard ball bearings, making them ideal for high-precision applications like pumps and machine spindles.

Self-aligning Ball Bearings

In applications where misalignment between the shaft and housing is a common issue, self-aligning ball bearings are a great choice. They are designed to accommodate shaft misalignment, making them ideal for agricultural machinery and construction equipment that may experience significant shifts in alignment during operation.

Type of Bearing | Description | Applications |

Ball Bearings | Used for handling radial and axial loads | Motors, conveyors, automotive applications |

Roller Bearings | Designed for heavy radial loads | Gearboxes, heavy machinery, automotive |

Thrust Bearings | Specially for axial loads | Automotive steering systems, turbines |

Magnetic Bearings | Avoids physical contact, uses magnets | High-speed trains, MRI machines |

Fluid Bearings | Uses pressurized fluid to support loads | Turbines, hydroelectric plants |

Roller Bearings

Roller bearings replace balls with cylindrical, tapered, or needle-shaped rollers, offering a larger contact area and higher load capacity. These bearings are suitable for applications that involve heavy-duty loads or where additional support is needed.

Cylindrical Roller Bearings

Used in machinery where high radial loads are common, cylindrical roller bearings are ideal for applications like gearboxes, conveyors, and heavy machinery. These bearings can handle high-impact conditions, providing reliable performance in demanding environments.Tapered Roller Bearings

These bearings can support both radial and axial loads, making them particularly useful in automotive wheel hubs, gearboxes, and applications where precise alignment and load distribution are crucial. Tapered roller bearings are often used in vehicles and machinery that undergo dynamic motion.

Needle Roller Bearings

Needle roller bearings are known for their compact size and ability to handle heavy radial loads. Due to their slim profile, they are perfect for applications where space is limited but heavy loads are still required. These bearings are commonly used in automotive components, textile machinery, and gearboxes.

Thrust Bearings

Thrust bearings are designed specifically to support axial loads—forces that are parallel to the shaft’s axis of rotation. These bearings are particularly useful in machinery that requires stability during high axial stresses.

Thrust Ball Bearings

Thrust ball bearings are ideal for handling axial loads in one direction. They are used in automotive steering systems, turbines, and industrial pumps. While they excel in axial load-bearing, they are not suited for radial loads, making them specialized for applications where axial forces dominate.

Thrust Roller Bearings

These bearings, using tapered or cylindrical rollers, support heavy axial loads and low-friction operation. They are commonly used in high-load applications like crane hooks, winches, and rolling mills. The ability to support large axial forces makes them essential for heavy-duty machinery.

Magnetic Bearings

Magnetic bearings leverage the properties of magnets to support rotating shafts without physical contact. This eliminates wear and reduces the need for lubrication, making them ideal for high-speed applications where traditional bearings would wear out quickly.

Active Magnetic Bearings

These bearings use electromagnets to levitate the shaft and adjust its position to maintain alignment. Active magnetic bearings are widely used in high-speed trains, medical devices like MRI machines, and precision machinery that requires minimal wear.

Passive Magnetic Bearings

Unlike active magnetic bearings, passive magnetic bearings use permanent magnets to maintain the shaft’s position. These bearings don’t require power input to function, making them suitable for applications where energy efficiency is key, such as in certain industrial machines.

Fluid Bearings

Fluid bearings use pressurized fluids to support loads, drastically reducing friction and wear. They are ideal for applications that require smooth, low-friction operation over long periods, especially in industries such as hydroelectric power generation and marine propulsion.

Hydrostatic Bearings

Hydrostatic bearings use pressurized liquid to support the shaft, offering minimal friction and high load capacity. They are ideal for turbines, generators, and other heavy-duty industrial machinery that operates under high-load conditions.

Hydrodynamic Bearings

Hydrodynamic bearings rely on fluid pressure generated by the motion of the shaft itself. These bearings are commonly used in marine propeller shafts, turbines, and other applications where shaft movement generates enough pressure to support the load.

Applications of Special Bearings

High-Speed Applications

Aerospace and Automotive Sectors

In industries like aerospace and automotive, special bearings are used in engines, gearboxes, and transmission systems where high-speed rotations are common. Bearings in these applications need to withstand extreme conditions, such as high temperatures and pressures.

Manufacturing Equipment

Special bearings are crucial in manufacturing equipment, including motorized spindles and conveyor systems. Their ability to reduce friction and support high-speed rotations leads to better performance, reduced energy consumption, and longer equipment lifespan.

Heavy Load Applications

Mining and Construction

For machinery involved in mining, construction, and heavy-duty operations, special bearings such as tapered roller bearings and spherical roller bearings are required. These bearings can withstand the extreme forces and harsh environments encountered in these industries.

Agriculture

Special bearings are designed for agricultural machinery, where they must endure challenging conditions like dirt, moisture, and extreme load demands. Bearings that support these machines need to be durable and efficient under varying conditions.

Industry | Bearing Type Used | Common Application |

Aerospace | Magnetic Bearings, Ball Bearings | Engines, turbine systems |

Automotive | Tapered Roller Bearings, Needle Bearings | Wheel hubs, gearboxes, transmissions |

Manufacturing | Deep Groove Ball Bearings | Motors, conveyor systems |

Construction | Spherical Roller Bearings | Cranes, construction equipment |

Agriculture | Self-aligning Ball Bearings | Farm equipment, machinery |

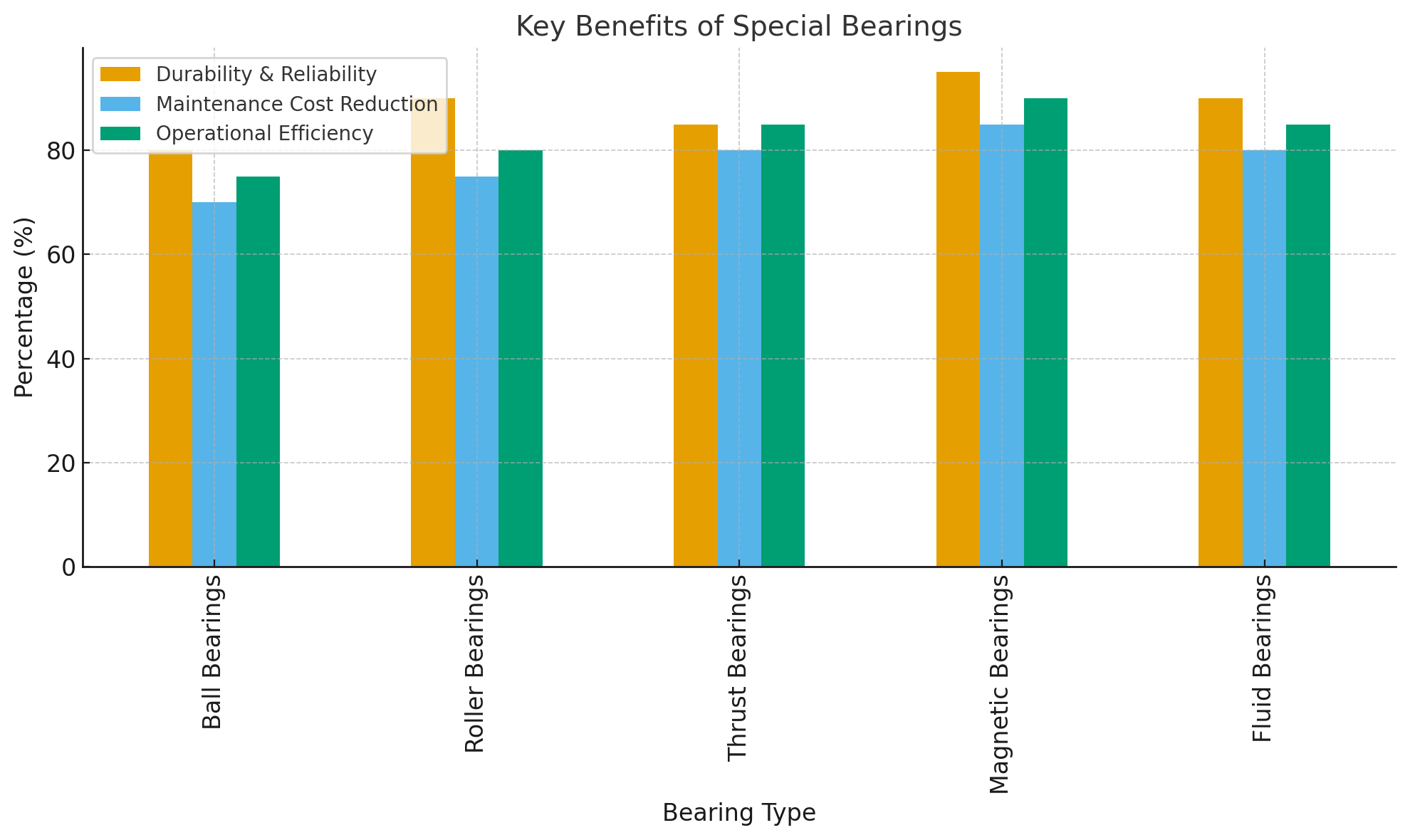

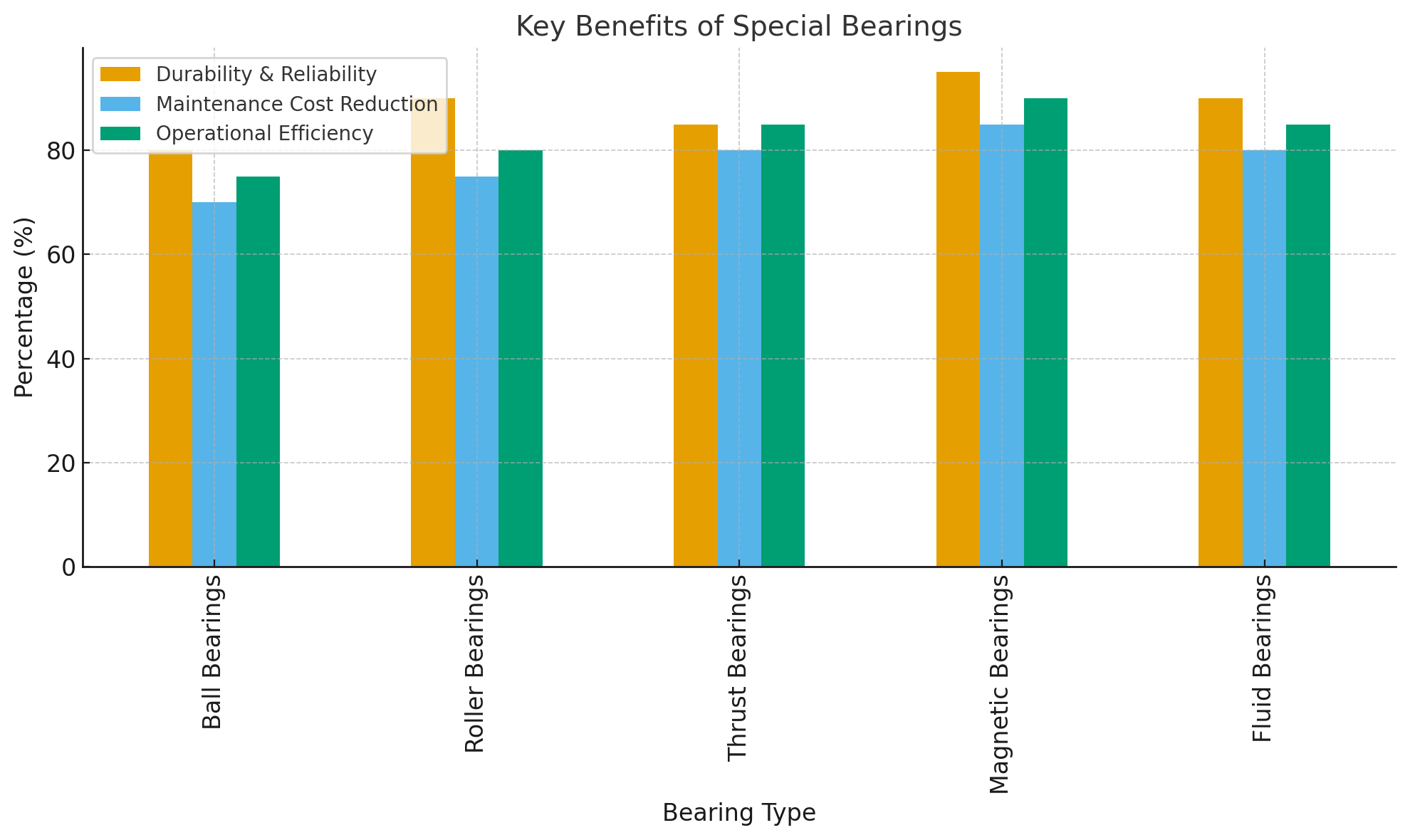

Key Benefits of Special Bearings

Improved Durability and Reliability

Special bearings are built to last longer under extreme operating conditions, which means they can provide better performance and greater reliability compared to standard bearings. This leads to longer equipment life and fewer replacements.

Reduced Maintenance Costs

By offering higher reliability and durability, special bearings reduce the need for frequent maintenance and replacements. Over time, this leads to significant cost savings for industries that depend on machinery for their operations.

Bearing Type | Maintenance Tip | Importance |

Ball Bearings | Regular lubrication and inspection | Prevents excessive wear and ensures longevity |

Roller Bearings | Monitor load limits and alignment | Reduces strain and prevents premature failure |

Thrust Bearings | Check for signs of axial wear | Ensures smooth operation in high-load areas |

Magnetic Bearings | Regular calibration and monitoring | Ensures optimal levitation and efficiency |

Fluid Bearings | Maintain fluid levels and quality | Ensures smooth operation and low friction |

Increased Operational Efficiency

Special bearings are designed to reduce friction, improve load capacity, and maintain stable performance in harsh environments. These benefits lead to smoother operations, reduced downtime, and improved overall system efficiency.

Factor | Description | Impact on Bearing Selection |

Load Capacity | The maximum weight the bearing can handle | Determines the type of bearing needed |

Speed | The speed at which the bearing will rotate | Affects bearing material and design |

Environmental Conditions | Temperature, humidity, and exposure to contaminants | Determines the bearing material and sealing method |

Lubrication | The method used to reduce friction | Affects bearing longevity and performance |

Cost | The expense of the bearing | Influences the selection for high-end vs. cost-effective solutions |

Conclusion

Special bearings are essential in industries like aerospace and agriculture. They address specific needs such as high-speed operations and heavy loads, ensuring machinery efficiency.

Selecting the right special bearing depends on operational requirements, load capacity, and environmental conditions. This choice maximizes performance and extends equipment life.

For industries aiming to improve equipment efficiency, EASIA bearings offers high-quality special bearings tailored to meet unique operational demands, ensuring reliability and long-term performance.

FAQ

Q: What is a special bearing?

A: A special bearing is a type of bearing designed to meet specific operational requirements, such as handling high speeds, heavy loads, or extreme environmental conditions.

Q: Why are special bearings needed?

A: Special bearings are needed when standard bearings cannot handle the unique demands of an application, such as high-speed rotations or extreme temperatures.

Q: What are the types of special bearings?

A: Special bearings include ball bearings, roller bearings, thrust bearings, magnetic bearings, and fluid bearings, each designed for different operational conditions.

Q: How do special bearings improve machinery performance?

A: Special bearings reduce friction, handle specific loads, and improve the durability and efficiency of machinery, resulting in reduced maintenance costs and extended equipment lifespan.

Q: Where are special bearings used?

A: Special bearings are used in industries like aerospace, automotive, agriculture, and manufacturing, where high-speed or heavy load-bearing is essential.

Q: What is the difference between special bearings and standard bearings?

A: Special bearings are engineered for specific, demanding conditions, whereas standard bearings are typically used in general applications with less extreme requirements.

Q: How do I choose the right special bearing?

A: The right special bearing depends on factors such as load capacity, speed, environmental conditions, and the specific needs of the machinery it will be used in.

English

English